| Porduct Name | 122mm X 60mm Half Curved Infrared Ceramic Panel Heater |

| Material | Ceramic |

| Voltage | 12V-480V,can be customized |

| Wattage | 125-1500W or customized |

| Shape | Flat/Curved/Bulb |

| Resistant wire element | Ni-Cr or FeCr |

| Useful wavelength range | 2 to 10 um |

| Average operating life | Up to 20,000 hrs depending on conditions |

| Internal thermocouple | K or J type |

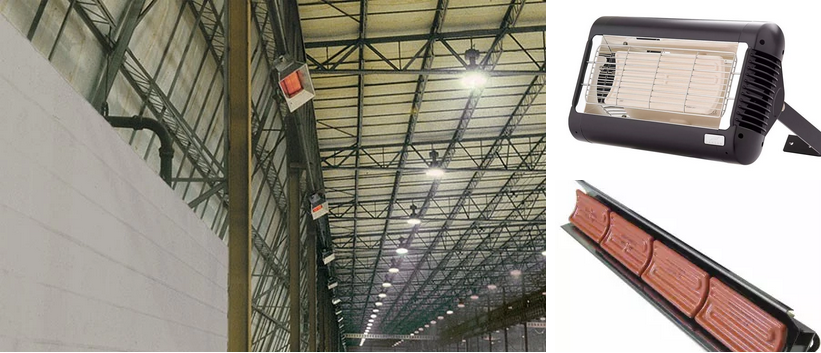

| Use | Infrared Ceramic Heater |

| Cold areas | Depends on length and diameter 5-25mm |

| Recommended radiation distance | 100mm to 200mm |

| Package | one heater with one box |

| Color | black,white,yellow |

|

The standard size of Infrared Ceramic Heater 1. 60*60mm 2. 120mmx60mm 3. 122mmx60mm 4. 120mm*120mm 5. 122mm*122mm 6. 240mm*60mm 7. 245mm*60mm With K or J type Thermocouple |

|

Resistive thermal conductors completely integrated in suitable ceramic materials make up ceramic infrared heaters. The heat conductor's service life is prolonged and it is kept from overheating because it is completely embedded in the ceramic, which allows the heat conductor's energy to be transferred to the surrounding material. Within the predetermined range of infrared radiation, the material utilized to embed the thermal conductor must be radioactively active, insulated, and have good absorption. Ceramic infrared heaters can be produced in a variety of geometric shapes to satisfy this demand.

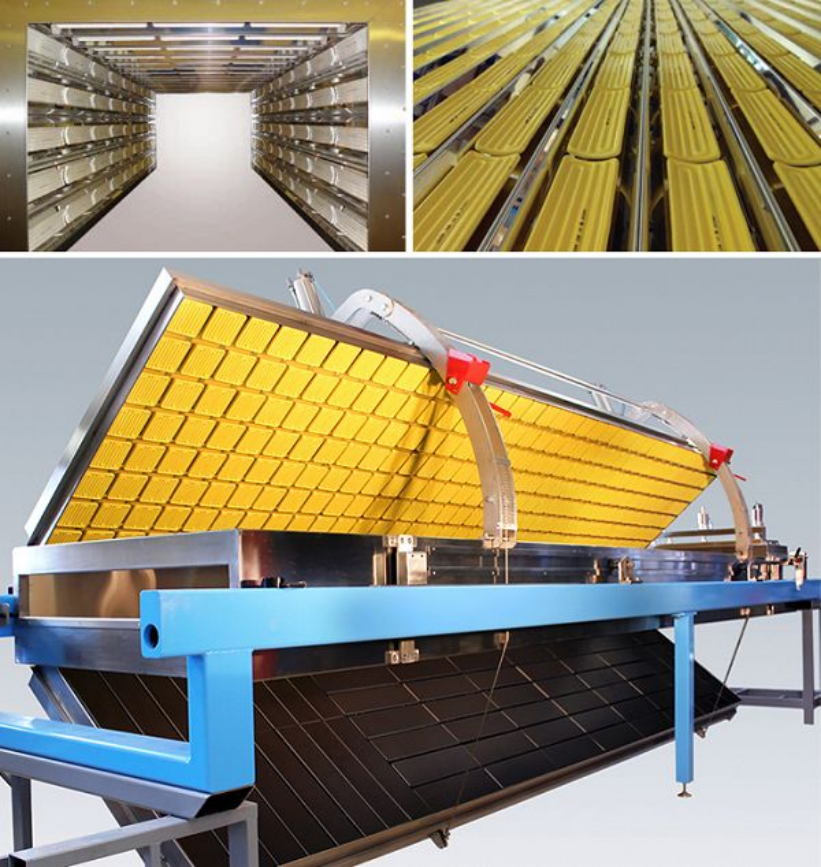

The ceramic infrared heater pad's main body incorporates a heating coil and employs a portion of its surface as a radiant surface. Another option is to fix a thermocouple for ceramic infrared heater plate.

1. Power line buried casting, no oxidation, impact resistance, permanent life, can control the temperature of the monomer, can also be arranged and heated, dense arrangement, up and down left and right, can obtain a more ideal uniform temperature, uniform temperature, no color glaze.

2. The Infrared Ceramic Panel Heater has the industrial standard size, and the heating wire on the heating surface is consistent with the wiring of other models

3. High heat resistance, high temperature does not burst, safe and reliable. Hollow heat insulation, heat acceleration.

4. The design rate ranges from 650W to 1600W, the higher operating temperature is 900℃, and the higher thermal power density is 68KW/m²

5. The curved surface design increases the distance between the heater back and the mounting position, and also facilitates the installation of round or curved heating systems. Infrared Ceramic Heater has a long history in ceramic infrared heaters and its performance is very stable.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314