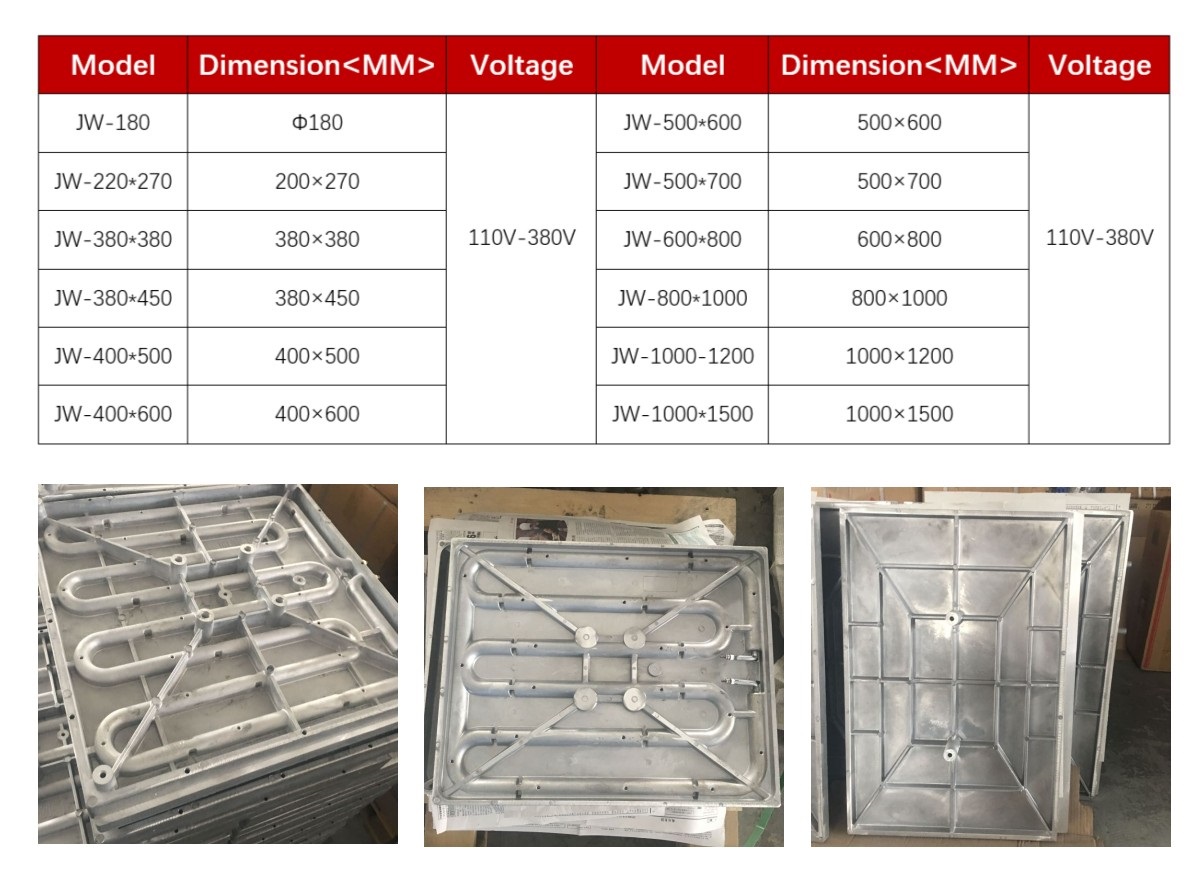

Product Paramenters

| Porduct Name | 150*200mm Aluminum Hot Plate Heater |

| Heating Part | Electric heating tube |

| Voltage | 110V-230V |

| Power | Customized |

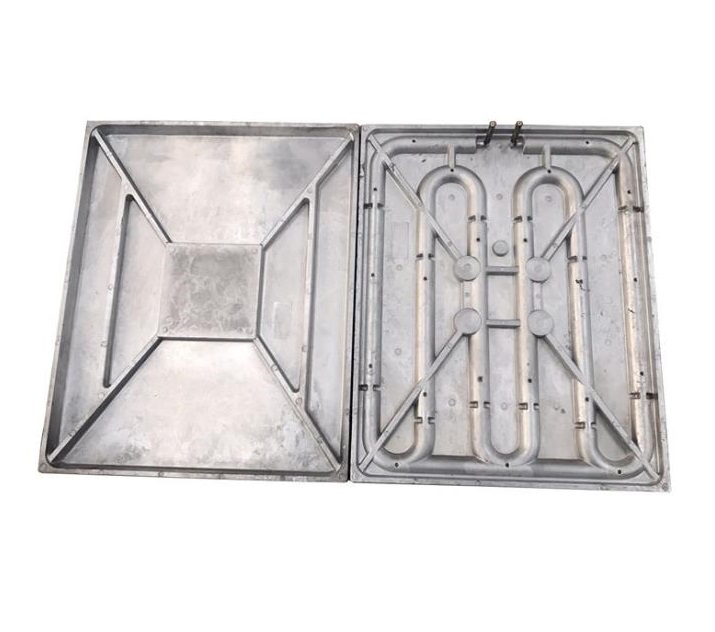

| One sets | Top heating plate+base bottom |

| Teflon Coating | Can be added |

| Size | 290*380mm,380*380mm,etc. |

| MOQ | 10 sets |

| Package | Packed in wooden case or pallet |

| Use | Aluminum heating plate |

|

The Aluminum Heating Plate for Heat Press Machine size as below: 100*100mm,200*200mm,290*380mm380*380mm,400*500mm,400*600mm,500*600mm,600*800mm,etc. We also have large size aluminum heat press plate,such as 1000*1200mm,1000*1500mm,and so on.These aluminum hot plates we have have the molds and if you need to be customized molds,pls send us the aluminum heating plate drawings (the mold fee need pay by yourself.) |

|

400*500mm

380*380mm

400*400mm

Product Configuration

Cast in aluminum hot heater is an electric heater with a tubular electric heating element and a high quality aluminum alloy material as the shell of a die casting. The temperature of the heater is generally between 150~450 degrees centigrade.It can be widely used in plastic machinery, die head, cable machinery, chemical, rubber, oil and other equipment.The cast aluminum heater plate features long life, good thermal insulation and strong mechanical properties.

We offer Casting Heating Plate precise design and manufacturing to meet our customer's mechanical, temperature and reliability requirements.Casting Heating Plate can be manufactured with one or multiple electrical heating elements with excellent thermal conductivity,to meet your specific design and thermal performance requirements.Our production capabilities range from large quantities of simple platens found in the food or semiconductor industries to complex geometries requiring secondary machining to meet the demands of your precision components.

Application

Aluminum hot plate is widely used in hot stamping machine, heat press machine,plastic machinery, mold, cable machinery, alloy die casting machine, pipeline, chemical industry, rubber, oil and other equipment.

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314