Product Paramenters

| Porduct Name | 245X60mm Infrared Ceramic Heater Panel |

| Material | Ceramic |

| Voltage | 12V-480V,can be customized |

| Wattage | 125-1500W or customized |

| Shape | Flat/Curved/Bulb |

| Resistant wire element | Ni-Cr or FeCr |

| Useful wavelength range | 2 to 10 um |

| Average operating life | Up to 20,000 hrs depending on conditions |

| Internal thermocouple | K or J type |

| Use | Infrared Ceramic Heater |

| Cold areas | Depends on length and diameter 5-25mm |

| Recommended radiation distance | 100mm to 200mm |

| Package | one heater with one box |

| Color | black,white,yellow |

|

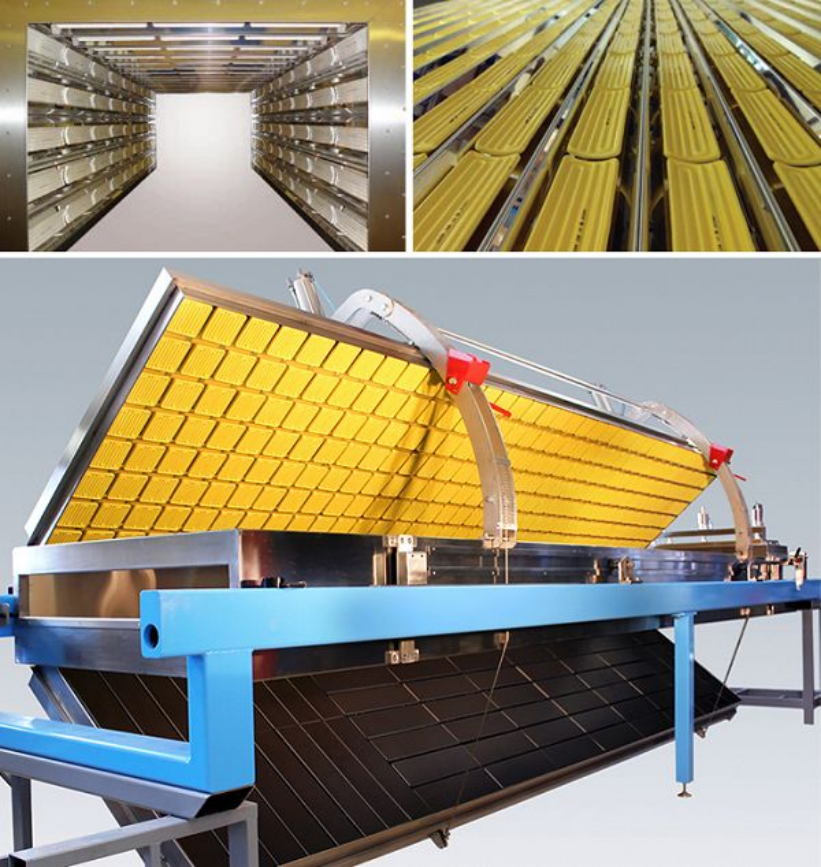

The standard size of Infrared Ceramic Heater 1. 60*60mm 2. 120mmx60mm 3. 122mmx60mm 4. 120mm*120mm 5. 122mm*122mm 6. 240mm*60mm 7. 245mm*60mm With K or J type Thermocouple |

|

Product Configuration

Ceramic infrared heating plate radiator is cast by ceramic hollow forming process, and air is used as the heat insulation material between the emission surface and the back. Compared with solid radiator, the preheating time is relatively shortened. The Infrared Ceramic Heater Panel maximum operating temperature is 630 ° C, the average surface electrical power density is up to 38.4KW/m², and the heating power range is from 60W to 600W.

Products Feature

1. Standard design: Operating voltage 230 volts, ceramic hollow casting process casting, wire length 85 mm.

2. Built-in thermocouple radiator: Built-in type K (NiCr-Ni) thermocouple model T-HFS,T-HFS/ 1,T-HFS/2,T-HFS/4, thermocouple connection wire length 100 mm.

3. Customized: Special power, special operating voltage, extended wire, "O" type wire connector

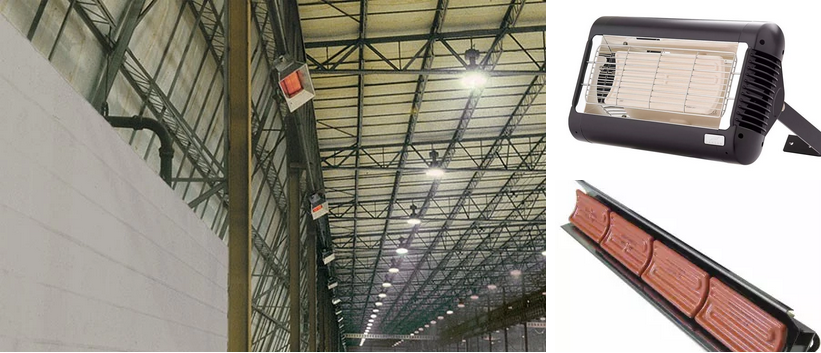

Product Applications

1. Heating in acid and alkali environment (e.g., shoe processing, tape, plywood heating).

2. Vibration or impact of large furnace body (e.g. : vacuum plastic machine, hot press forming machine)

3. Short distance rapid heating (example: printing ink drying oven, circuit board repair table, electric heating table). And other industries of infrared radiation heating

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314