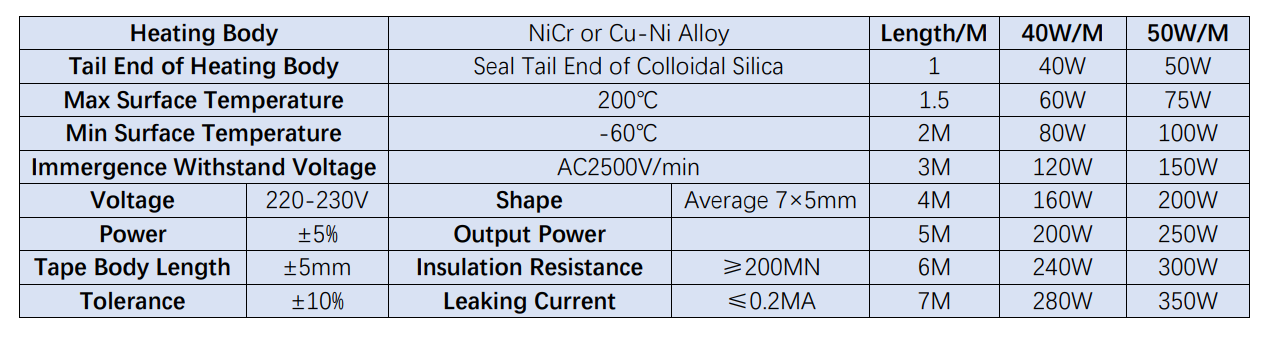

Product Paramenters

| Porduct Name | 80W 2M Drain Line Heater Wire |

| Material | Silicone rubber |

| Size | 5*7mm |

| Heating length | 0.5M-20M |

| Lead wire length | 1000mm,or custom |

| Color | white,grey,red,blue,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

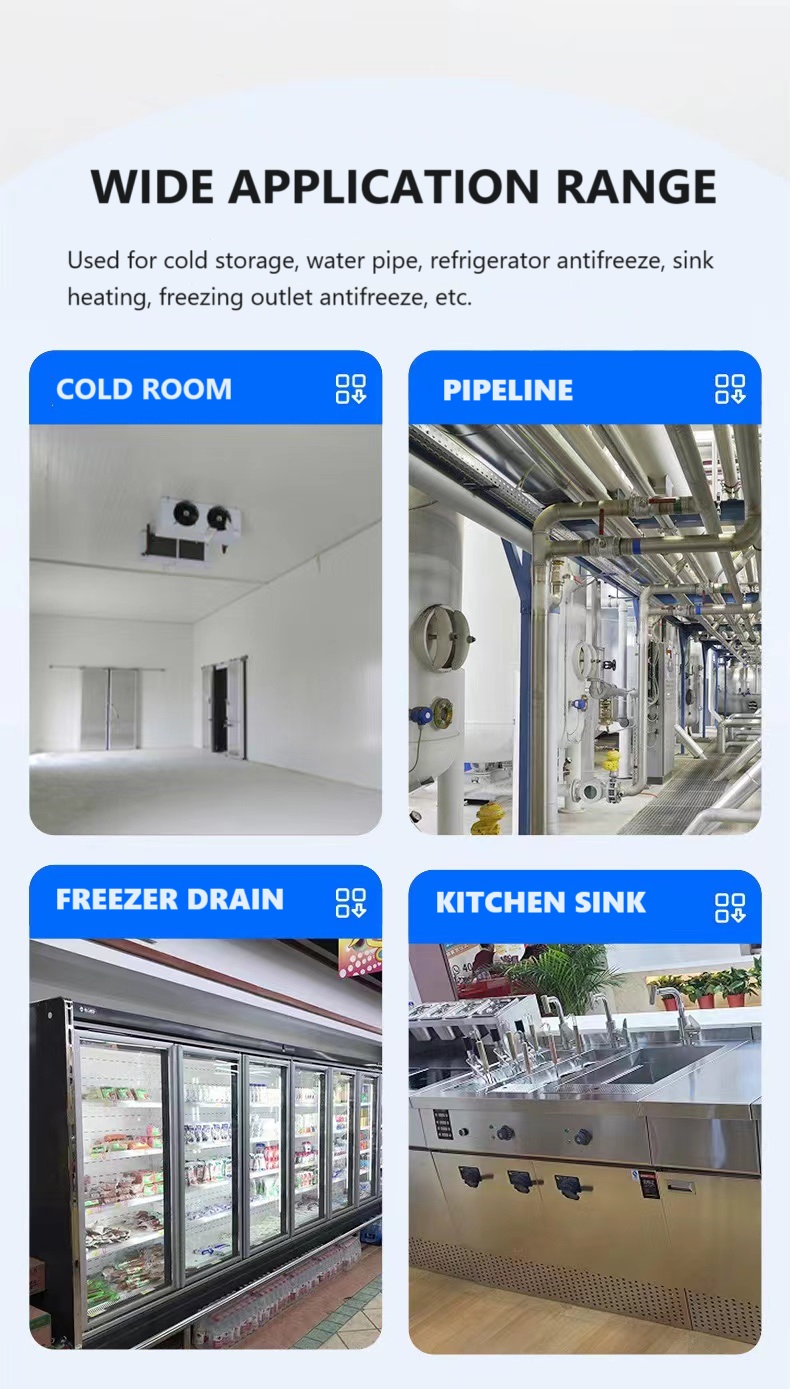

| Use | Drain pipe heater |

| Certification | CE |

| Package | one heater with one bag |

|

The power of drain pipeline heating belt is 40W/M,we can also be made other powers,such as 20W/M,50W/M,etc.And the length of drain pipe heater have 0.5M,1M,2M,3M,4M,etc.The longest can be made 20M. The package of drain line heater is one heater with one transplant bag,customized bag quantity at list more than 500pcs for each length. |

|

Product Configuration

Water from defrosting refrigeration units placed in cold rooms is drained using a special type of cable called drain pipe heater cable, which is placed inside the pipe. They are only active during the cycle of thawing. The cooler fins in cold storage will eventually accumulate ice, which needs to be cleared off. To melt the ice, resistance is placed between the fins; a drain pipe collects and treats the water. The cold storage contains several meters' worth of drains, which could cause the water to refreeze. You must insert the drainpipe heating cable into the pipe in order to prevent this issue. Only during the defrost cycle is it opened.

Heating cables for drain pipe can be obtained with a specified length of cold tail; they are manufactured and tested in a factory setting under strict control.

Product Features

1. Waterproof design: to guarantee the heating belt's safe operation in humid environments and to avert damage and short circuits.

2. Double layer insulator: lowers the chance of current leakage and adds further safety protection.

3. Molded joints: Verify that the heating belt's connecting section is durable and has good sealing.

4. Silicone rubber insulator: appropriate in a range of tough environments and acceptable for temperatures between -60°C and +200°C.

5. Material for the heating body: often an alloy of copper and nickel-chromium, these materials offer great temperature resistance and strong electrical conductivity.

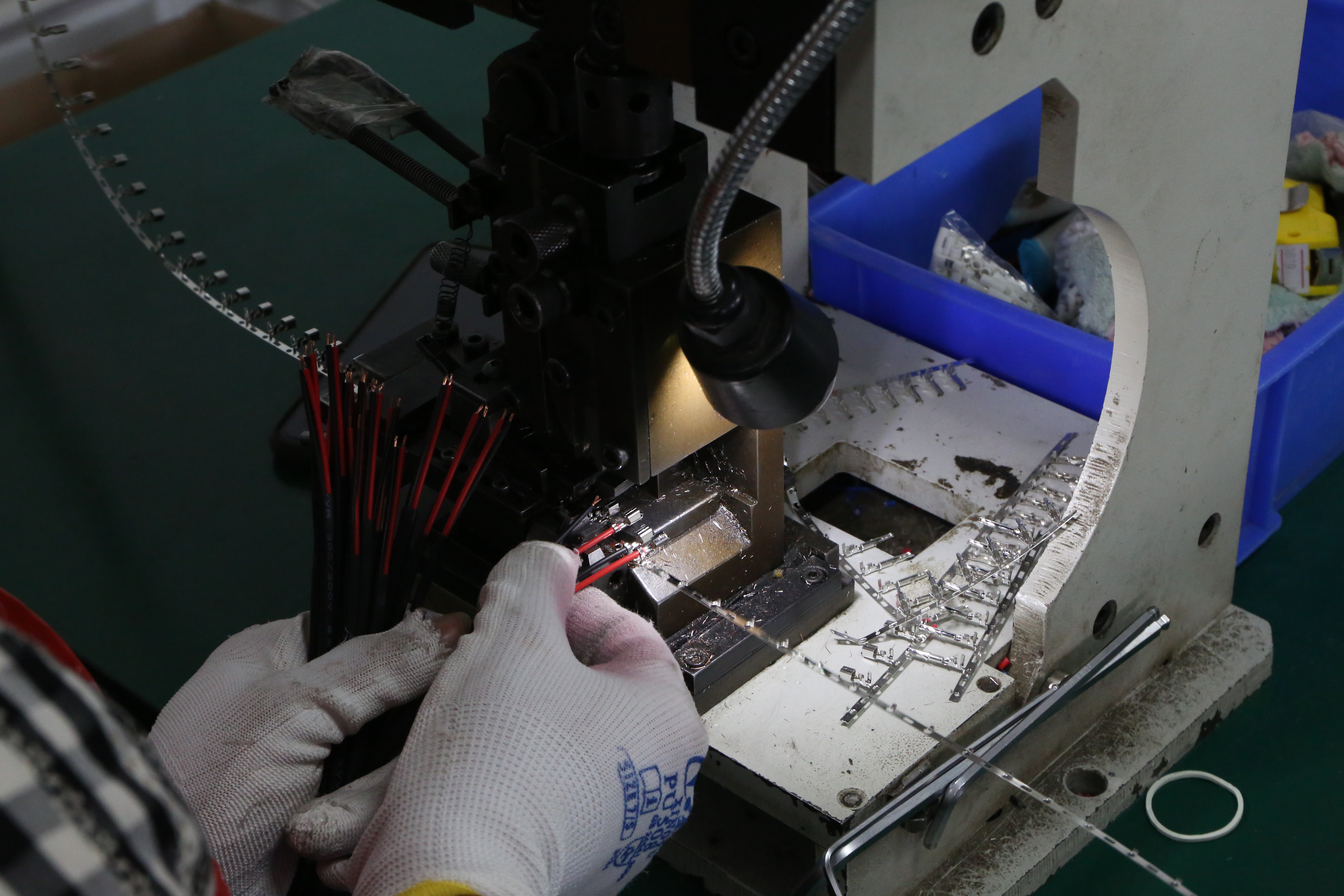

Factory Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314