Product Configuration

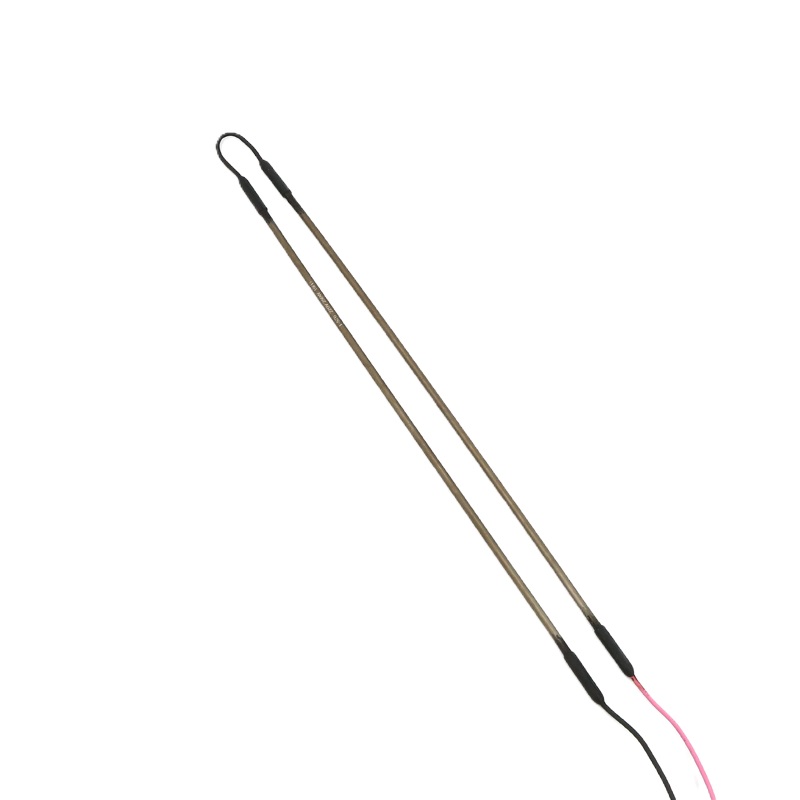

The silicone compressor crankcase heating tape is a flexible heating element used to heat a crankcase or other industrial equipment. The compressor part crankcase heater is composed of silicone insulation layer and internal heating wire, with high temperature resistance, aging resistance, waterproof and moisture-proof characteristics, suitable for various industrial heating occasions.

The main application scenarios of silicone rubber crankcase heating tapes include but are not limited to air conditioning compressor crankcase heating, pipeline heating, and anti-freeze silicone rubber heating belts.

Product Paramenters

| Porduct Name | Compressor Crankcase Heater Heating Tape |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Material | silicone rubber |

| Width of belt | 14mm,20mm,25mm,etc. |

| Length of belt | Customized |

| Resistant voltage | 2,000V/min |

| Insulated resistance in water | 750MOhm |

| Use | Crankcase heater belt |

| Lead wire length | 1000mm,or custom |

| Package | one heater with one bag |

| Approvals | CE |

| Company | factory/supplier/manufacturer |

|

The compressor part crankcase heating tape width can be made 14mm,20mm,25mm,30mm,and so on.The silicone rubbeer heating belts can be used for air-conditioner compressor or cooler fan cylinder defrosting.The crankcase heater belt length can be customized as client’s requirements. |

|

1. Voltage: Common voltage is 12V, 24V, 110V, 220V and so on.

2. Power: Depending on the crankcase heating tape size and design, the power range is wide (such as 10W/m to 100W/m).

3. Temperature range: usually -60°C to 200°C, special models can withstand higher temperatures.

4. Width of belt : Generally 14mm and 20mm,also can be made 25mm,30mm,35mm,etc.

5. Length: The crankcase heater tape can be customized according to requirements.

Product Features

Product Application

*** Automobile industry: Used for heating crankcase, engine, fuel tank and other components to prevent difficult starting at low temperatures.

*** Industrial equipment: Insulation or heating for pipes, valves, pump bodies, storage tanks and other equipment.

*** Food industry: Used for heating in food processing equipment, meeting food-grade safety requirements.

*** Medical equipment: Constant temperature control for medical equipment.

Aerospace: Anti-freezing heating for aircraft components.

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314