| RLPV | RLPG | |

| Dimension | Any dimension on request | |

| Voltage | Any voltage on request | |

| output | up to 2.5kw/m2 | |

| Tolerances | ≤±5% | |

| surface temperature | -30 C~110 C | |

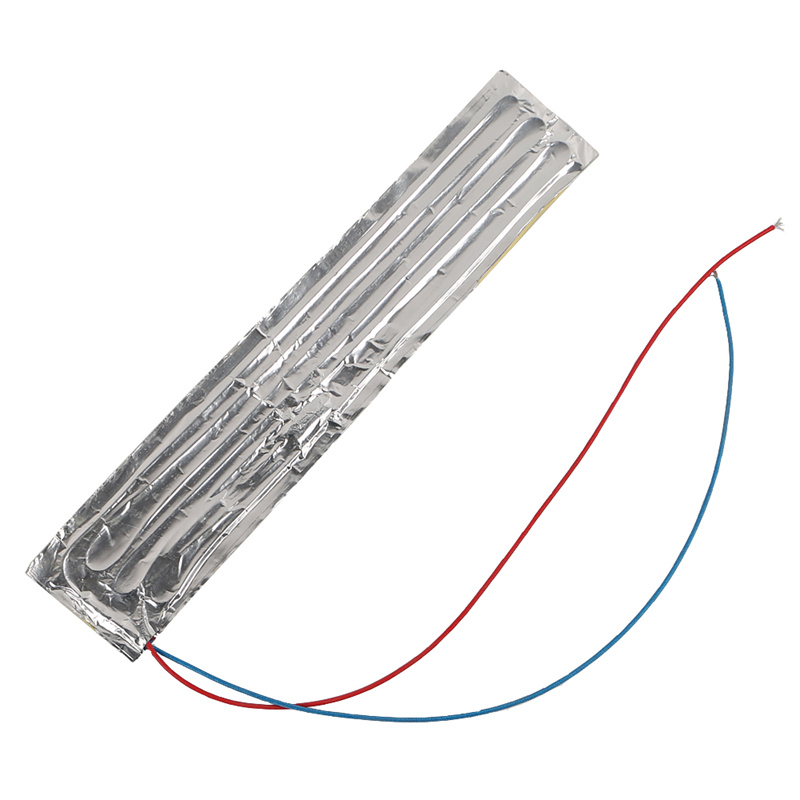

Very thin (e.g., 50 m) etched metal foil (often a nickel-based alloy) is used as the resistance element in Polyimide (Kapton) heaters. The desired resistance pattern is produced by processing the foil with acid spray after designing the resistance pattern to be etched in CAD and transferring it to the foil.

| Max. element temp | 220 (428) .°C, (°F) | Dielectric strength at 20°C | 25 ASTM KV/m |

| Bending radius | ≥0.8mm | Dielectric | > 1000V/min |

| Wattage Density | ≤ 3.0 W/cm2 | Watt tolerance | ≤ ±5% |

| Insulation | > 100M ohm | Thickness | ≤0.3mm |

| Temperature Sensor | RTD / film pt100 | Thermistor / NTC | thermal switch etc |

| Adhesive backin | silicone based PSA | Acrylic based PSA | polyimide based PSA |

| Lead wires | Silicone rubber cables | Fiberglass insulated wire | different plug set / termination available |

1. Ice box or refrigerator freeze or defrost prevention

2. Plate heat exchangers with freeze protection

3. Keeping heated food counters in canteens at a consistent temperature

4. Electronic or electric control box anti-condensation

5. Heating from hermetic compressors

6. Mirror de-condensation in bathrooms

7. Refrigerated display cabinet anti-condensation

8. Home and office equipment, medical...