|

NO. |

Item |

Unit |

Indicator |

Remarks |

|

1 |

Size and Geometry |

mm |

Conforms to user drawing requirements |

|

|

2 |

Deviation of resistance value |

% |

≤±7% |

|

|

3 |

Insulation resistance at room temperature |

MΩ |

≥100 |

founder |

|

4 |

Insulation strength at room temperature |

|

1500V 1min No breakdown or flashover |

founder |

|

5 |

Operating temperature (per meter of wire length) leakage current |

mA |

≤0.2 |

founder |

|

6 |

Terminal connection strength |

N |

≥50N1min Not unusual |

Upper terminal of wire |

|

7 |

Intermediate connection strength |

N |

≥36N 1min Not unusual |

Between the heating wire and the wire |

|

8 |

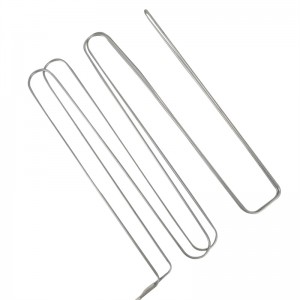

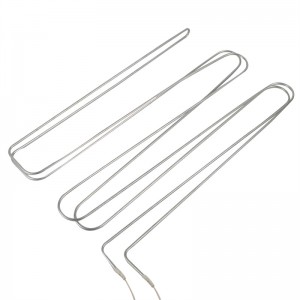

Aluminum tube bending diameter retention rate |

% |

≥80 |

|

|

9 |

Overload test |

|

After the test, no damage, still meet the requirements of Article 2,3 and 4 |

At the permissive operating temperature |

|

Current of 1.15 times rated voltage for 96h |

1.Humidity state insulation resistance ≥200MΩ

2.Humidity leakage current≤0.1mA

3.Surface load≤3.5W/cm2

4.Working temperature: 150℃(max. 300℃)

1. Installation is simple.

2. Rapid heat transfer.

3. Prolonged heat radiation transmission.

4. High resistance against corrosion.

5. Constructed and designed for security.

6. Economical cost with great efficiency and a long service life.

Aluminum tube heating elements are simpler to use in confined spaces, have excellent deformation capabilities, are adaptable to all types of spaces, have outstanding heat conduction performance, and enhance heating and defrosting effects.

It is frequently used to defrost and maintain heat for freezers, refrigerators, and other electrical equipment.

Its rapid speed on heat and equality, security, through thermostat, power density, insulating material, temperature switch, and heat scatter circumstances can be necessary on temperature, mostly for defrosting refrigerators, defrosting other power heat appliances, and other uses.