Product Configuration

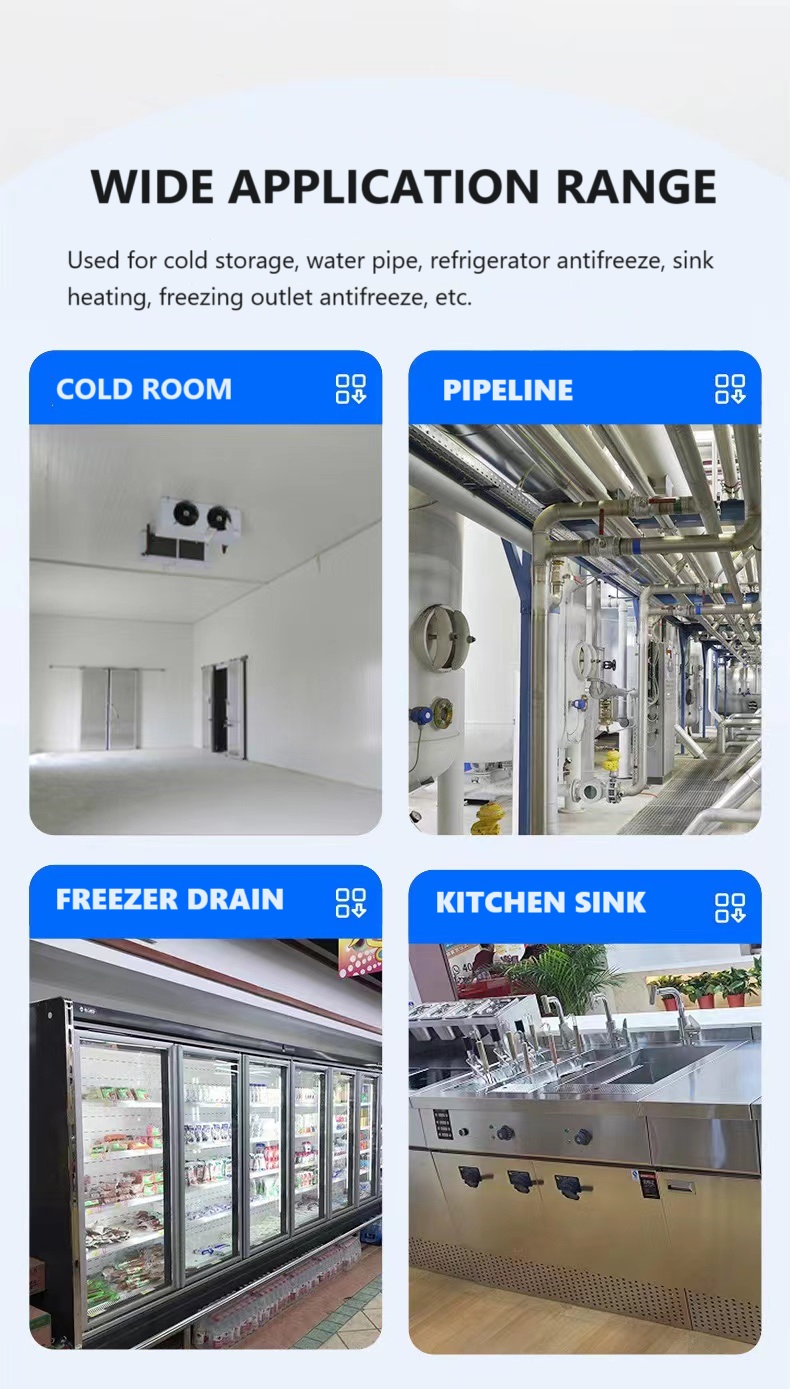

Defrost braid heating cable has heat resistance and is used in refrigerators, freezers, air conditioners, water dispensers, rice cookers and other household appliances. The average power density is generally below 40w/m, and in a low temperature environment with good heat dissipation, the power density can reach 60w/m, and the use temperature is -60°C+155°C.

According to the different use characteristics of defrost silicone heating wire, our company has two kinds of silicone rubber defrost heating cable: parallel constant power silicone rubber defrost heating wire and self-limiting silicone rubber defrost heating wire.

Product Paramenters

| Porduct Name | Defrost Braid Heating Cable |

| Insulation Material | Silicone rubber |

| Wire diameter | 2.5mm,3.0mm,4.0mm,etc. |

| Heating length | customized |

| Lead wire length | 1000mm,or custom |

| Color | white,grey,red,blue,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | defrost heating wire |

| Certification | CE |

| Package | one heater with one bag |

|

The Defrost Braid Heating Cable length,voltage and power can be customized as required.The wire diameter can be choosed 2.5mm,3.0mm,3.5mm,and 4.0mm.The wire surface can be braided firberglass,aluminum or stainless steel. The defrost wire heater heating part with lead wire connector can be seal with rubber head or double-wall shrinkable tube,you can choose according to your own use needs. |

|

Product Features

1. Good temperature resistance. The whole adopts silicone rubber as insulation and thermal conductivity material, including power cord), and the working ambient temperature is -60 to +200℃

2. Good thermal conductivity: Through the generation of heat, direct heat conduction, high thermal efficiency, short-term heating to achieve the effect.

3. Reliable electrical performance: When each electric heating belt leaves the factory, it passes strict DC resistance, immersed high voltage and insulation resistance test to ensure quality.

4. Strong structure, flexibility and easy to bend; There is no binding point in the integrated cold tail section. Reasonable structure, easy to install.

5. Strong designability; Heating length, lead length, rated voltage. The power is determined by the user.

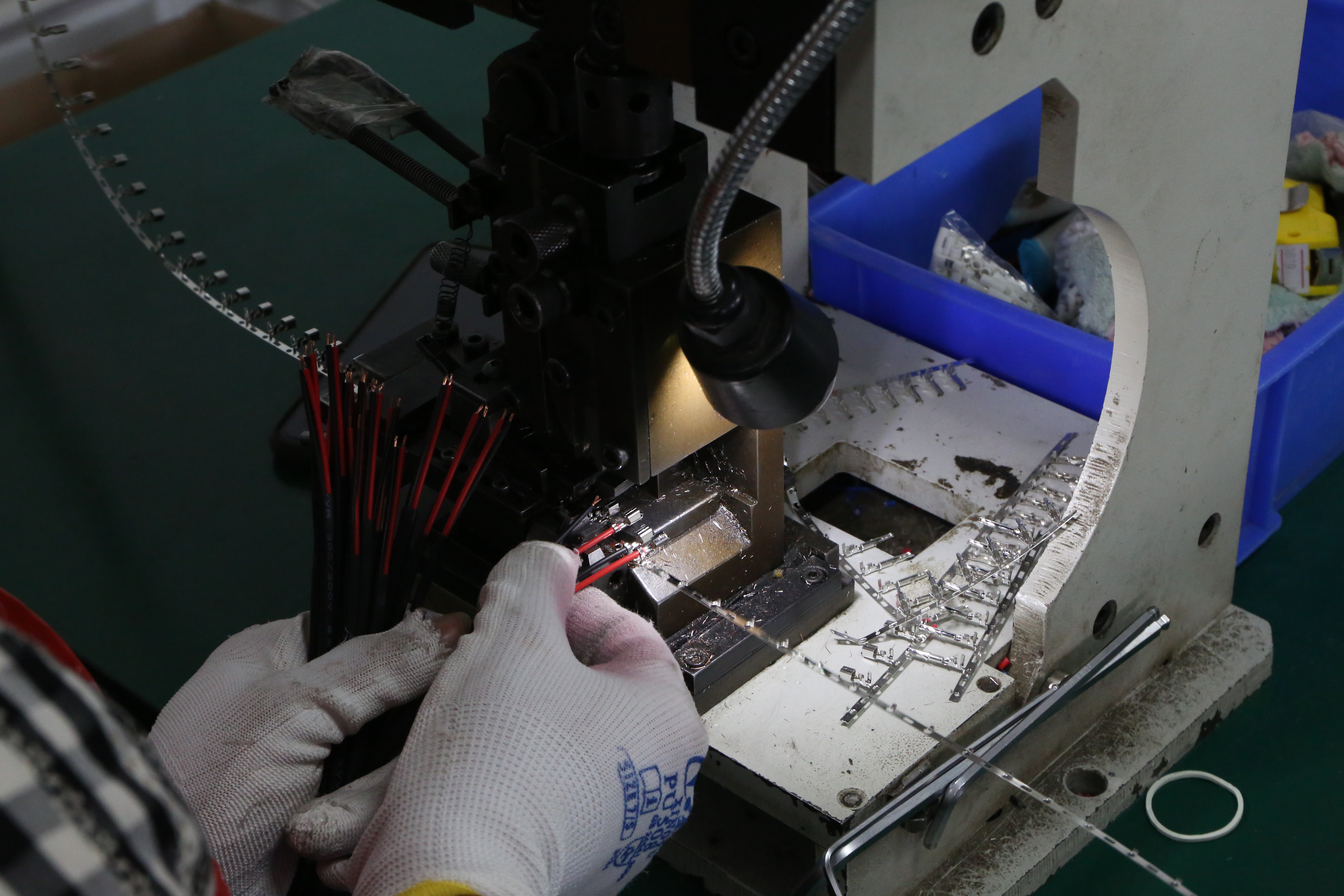

Producing Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314