| Porduct Name | Defrost Heater Element |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Defrost Heating Element |

| Tube length | 300-7500mm |

| Lead wire length | 700-1000mm (custom) |

| Approvals | CE/ CQC |

| Terminal type | Customized |

|

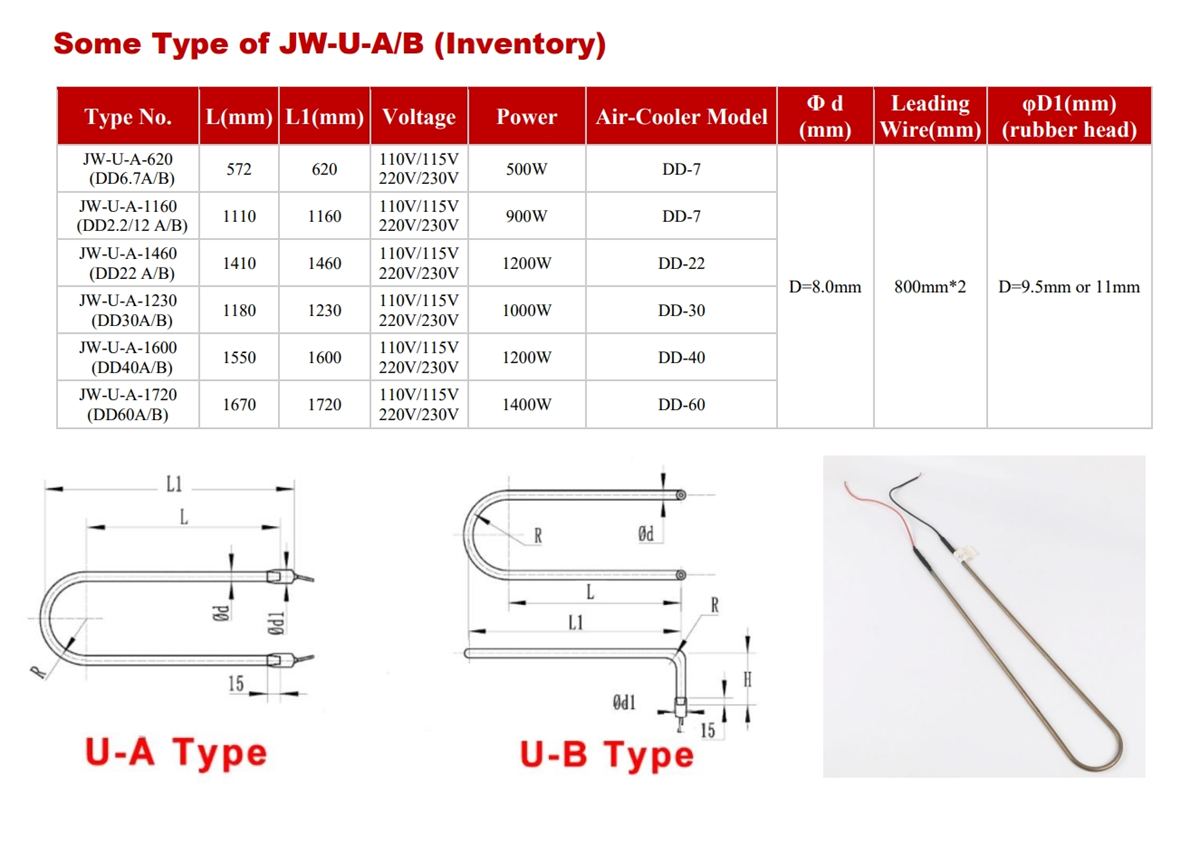

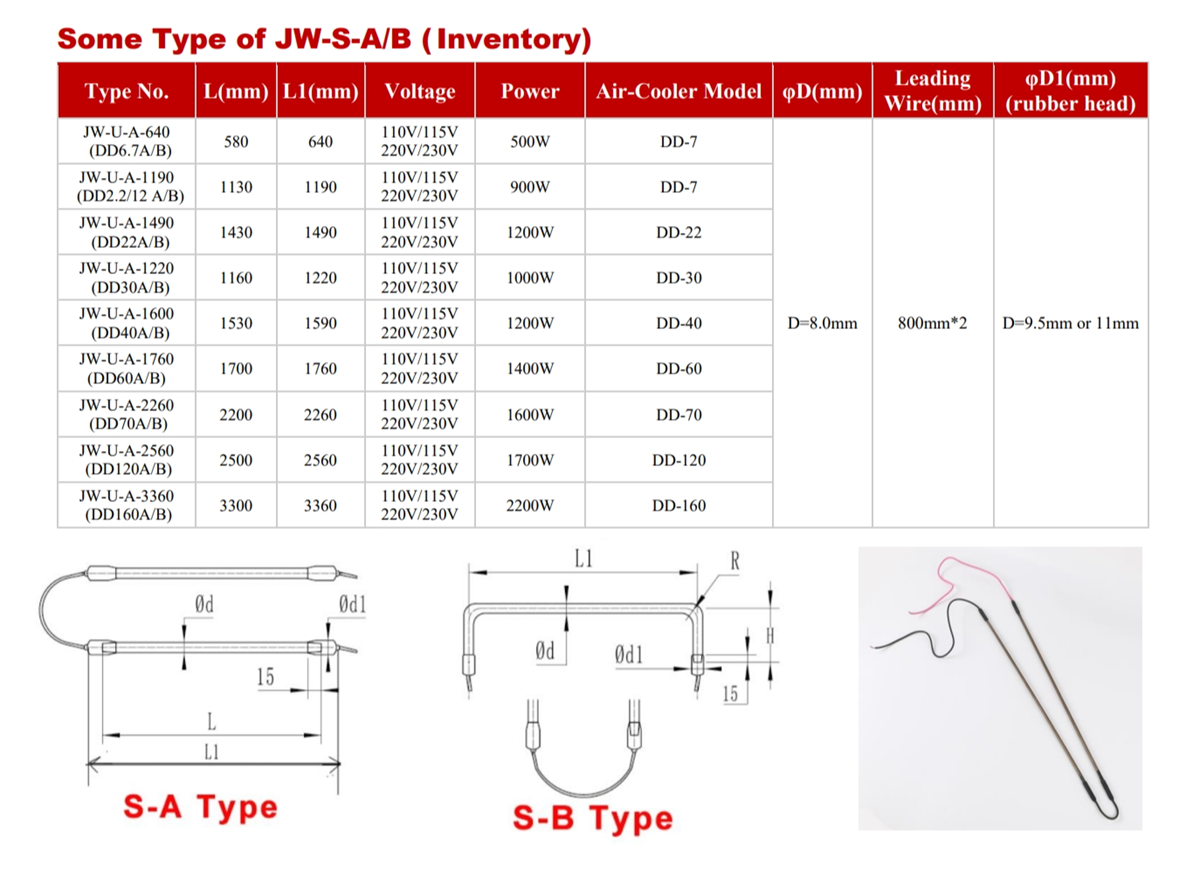

The defrost heater element shape have single straight tube,double straight tube,U shape,W shape,and any other custom shape.The defrost heating element tube diameter can be choosed 6.5mm,8.0mm,10.7mm. The defrost heater part with the lead wire is sealed by rubber head,can also be choosed seal by shrinkable tube. |

|

The heating principle of the defrost heater element is to distribute high temperature resistance wire uniformly in the high temperature resistant stainless steel pipe, and fill the void with crystalline magnesium oxide powder with good thermal conductivity and insulation properties. This structure is not only advanced, but also has high thermal efficiency, and even heating. When there is current passing through the high temperature resistance wire, The heat generated is diffused to the surface of the metal tube through the crystalline magnesium oxide powder, and then transferred to the heated part or the air, so as to achieve the purpose of heating. Because the shell of defrost heater is made of metal material, it can resist dry burning, corrosion resistance and high temperature resistance, and can adapt to many heating environments. And tubular defrost heater can be made into a variety of shapes, to meet the various installation needs of customers.

Defrost heaters are mainly used in refrigeration and freezing systems to prevent the build-up of frost and ice.

The defrost heating tube applications include:

1. Refrigerator: Install a defrosting heater in the refrigerator to melt ice and frost accumulated on the evaporator coil, ensuring efficient operation of the equipment and maintaining a consistent temperature for food storage.

2. Freezer: Freezer uses defrost heater tube to prevent the evaporator coil from freezing, so that the airflow is smooth and the frozen food is effectively preserved.

3. Commercial refrigeration units: Tubular Defrost heaters are essential in large refrigeration units used in supermarkets, restaurants and other commercial environments to maintain the integrity of perishable goods.

4. Air conditioning system: In air conditioning units with cooling coils that are prone to frost formation, defrost heaters are used to melt ice and improve the cooling efficiency of the system.

5. Heat pump: Defrosting heaters in heat pumps help prevent frost buildup on outdoor coils in cold weather, ensuring optimal system performance in both heating and cooling modes.

6. Industrial refrigeration: Industries that require large-scale refrigeration, such as food processing and storage facilities, use defrost heaters to maintain the efficiency of their refrigeration systems and ensure product quality.

7. Cold rooms and walk-in freezers: defrost heating tubes are used in cold rooms and walk-in freezers to prevent freezing of evaporator coils and maintain a consistent temperature for mass storage of perishable items.

8. Refrigerated display cases: Businesses like grocery and convenience stores use refrigerated display cases with defrost heaters to display refrigerated or frozen products without the risk of frost obstructing visibility.

9. Refrigerated trucks and containers: defrost heaters are used to refrigerate transport systems to prevent ice buildup and ensure that goods are kept in optimal condition during transport.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314