Product Configuration

Due to the characteristics of high indoor humidity, low temperature and frequent cold and hot impact when the refrigeration equipment is working, defrost heater pipe is generally based on tubular electric heating elements with high quality modified magnesium oxide as filler and stainless steel as shell. After being reduced, the wiring end is sealed by special rubber. The defrost heater pipe can be used normally in the refrigeration equipment. It can be bent in any shape according to the user's needs, and it is more convenient to be embedded on the fin inside the cooler, or the surface of the refrigerator evaporator, or the bottom of the water tray and other parts for defrosting.

1. defrost heater pipe shell pipe: generally 304 stainless steel, good corrosion resistance.

2. Internal heating wire of defrost heater pipe: nickel chromium alloy resistance wire material.

3. The port of defrost heater pipe is sealed with vulcanized rubber.

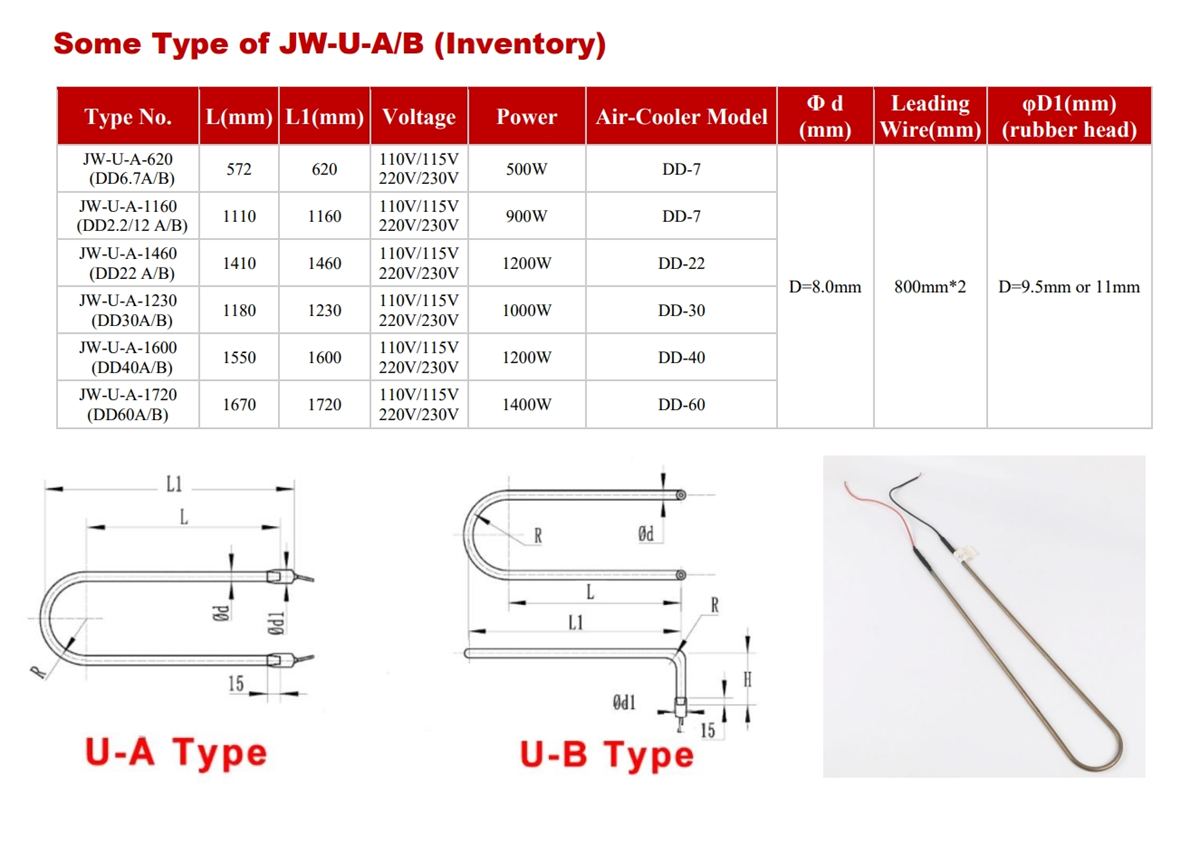

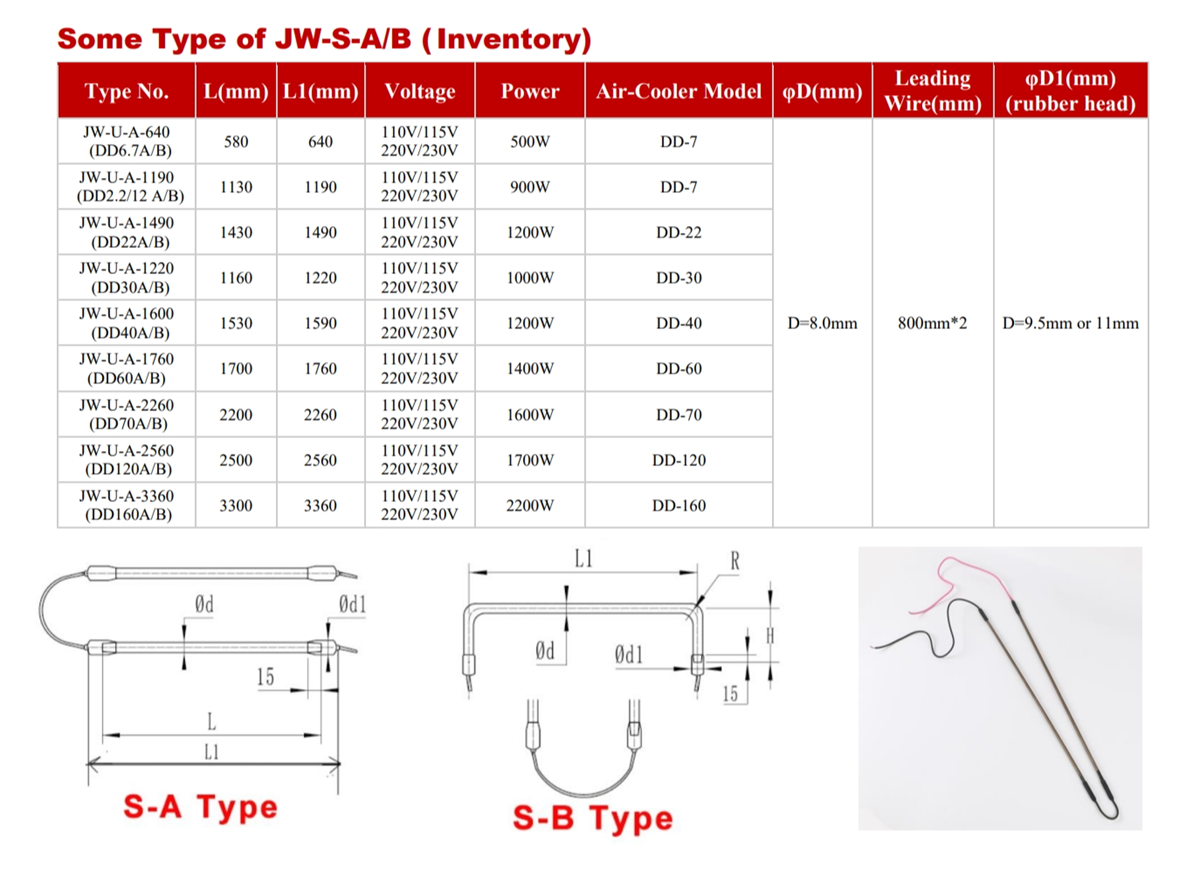

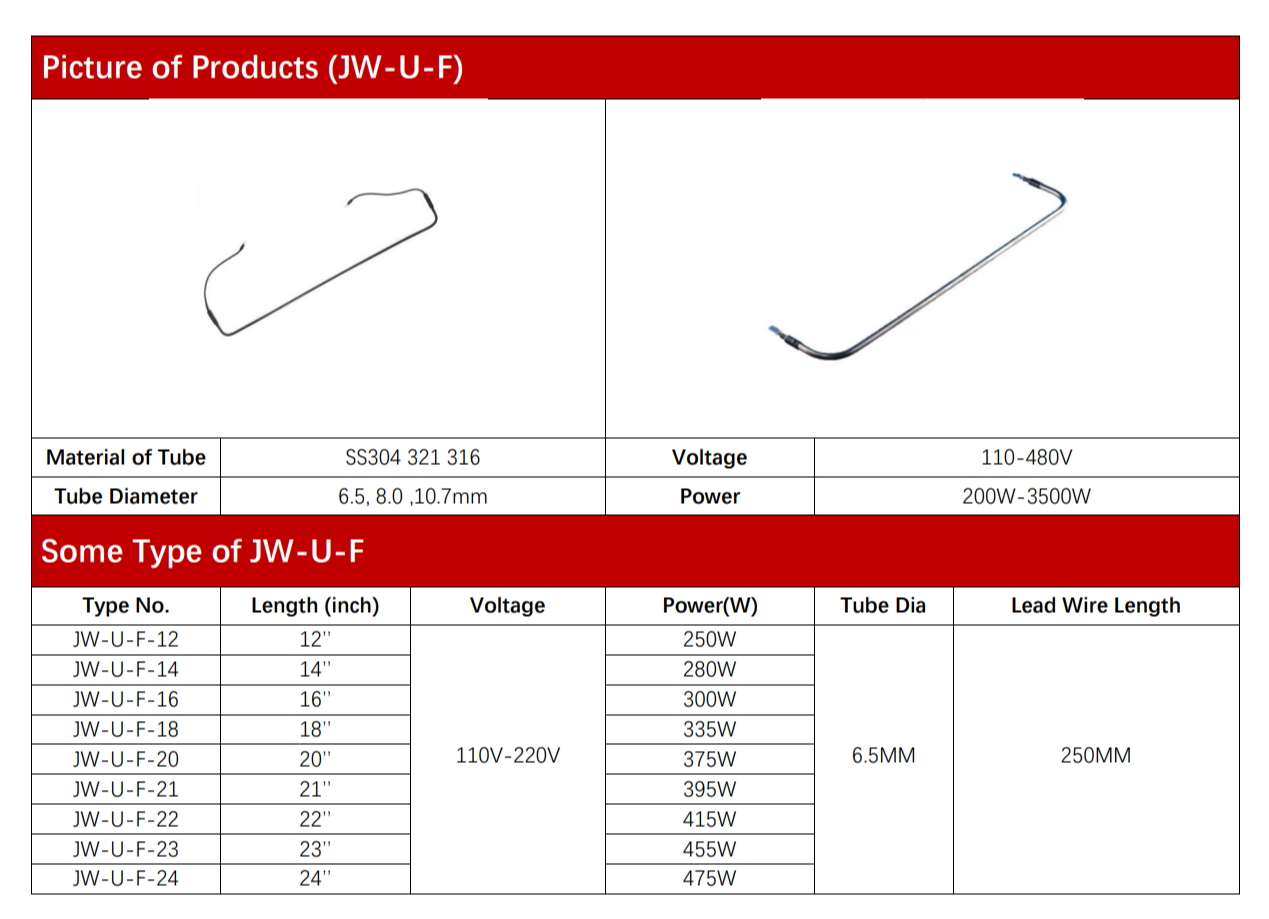

Product Paramenters

How to Use defrost Heater Correctly

In order to ensure the normal work and extend the service life of defrost heater pipe, the following points should be paid attention to:

1. Avoid scratches and damage to the surface of defrost heater pipe.

2. In the use of defrost heater pipe, to ensure the stability of the power supply, you can be equipped with a voltage stabilizer.

3. Check the working state and resistance value of defrost heater pipe regularly, and solve the problem in time.

4. Avoid using defrost heater pipe in high temperature and humid environment, so as not to cause safety problems.

Defrost Heater for Air-cooler Model

Product Application

Defrost heater pipes are primarily used in refrigeration and freezing systems to prevent the buildup of frost and ice. Their applications include:

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314