| Porduct Name | Defrost Tubular Heater |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Tube diameter | 6.5mm,8.0mm,10.7mm etc. |

| Power | 300-400W per meter |

| Length | Customized |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Defrost Heating Element |

| Tube material | SS304,SS316 |

| Protection class | IP00 |

| Approvals | CE/CQC |

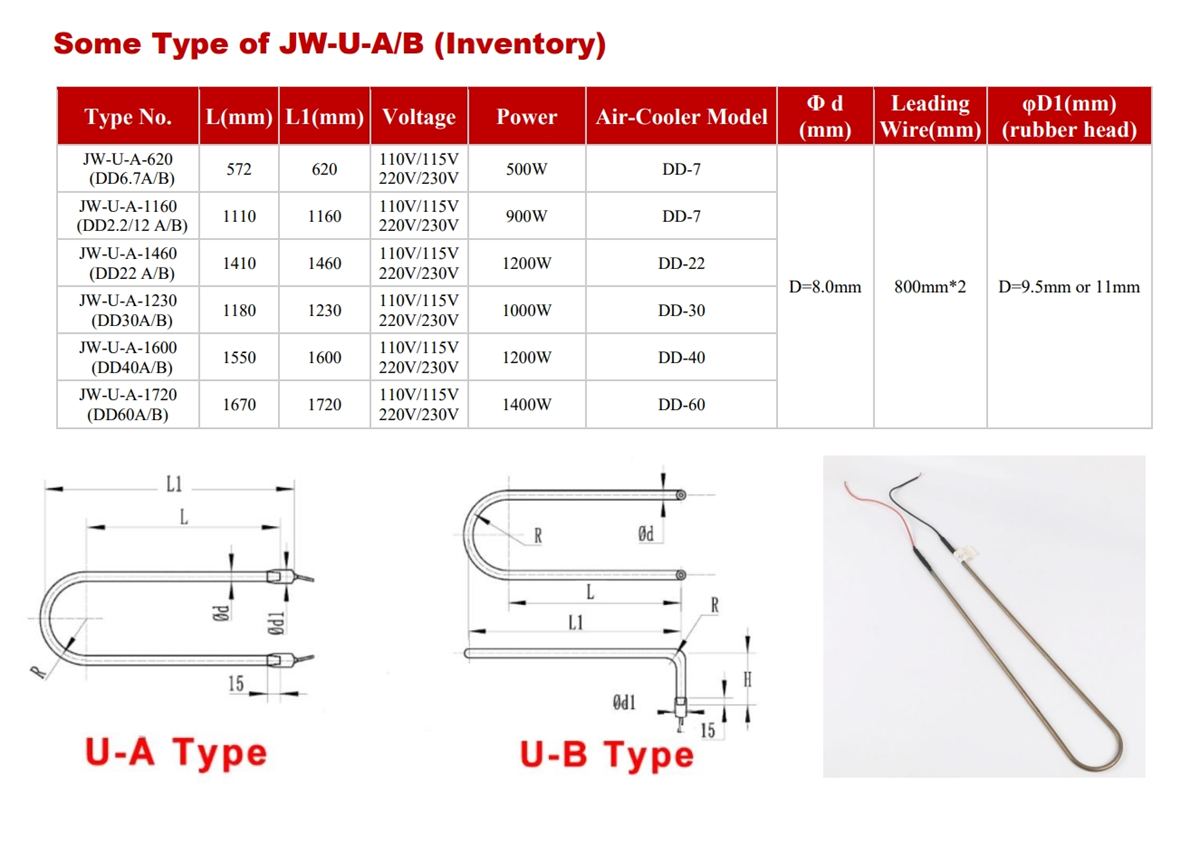

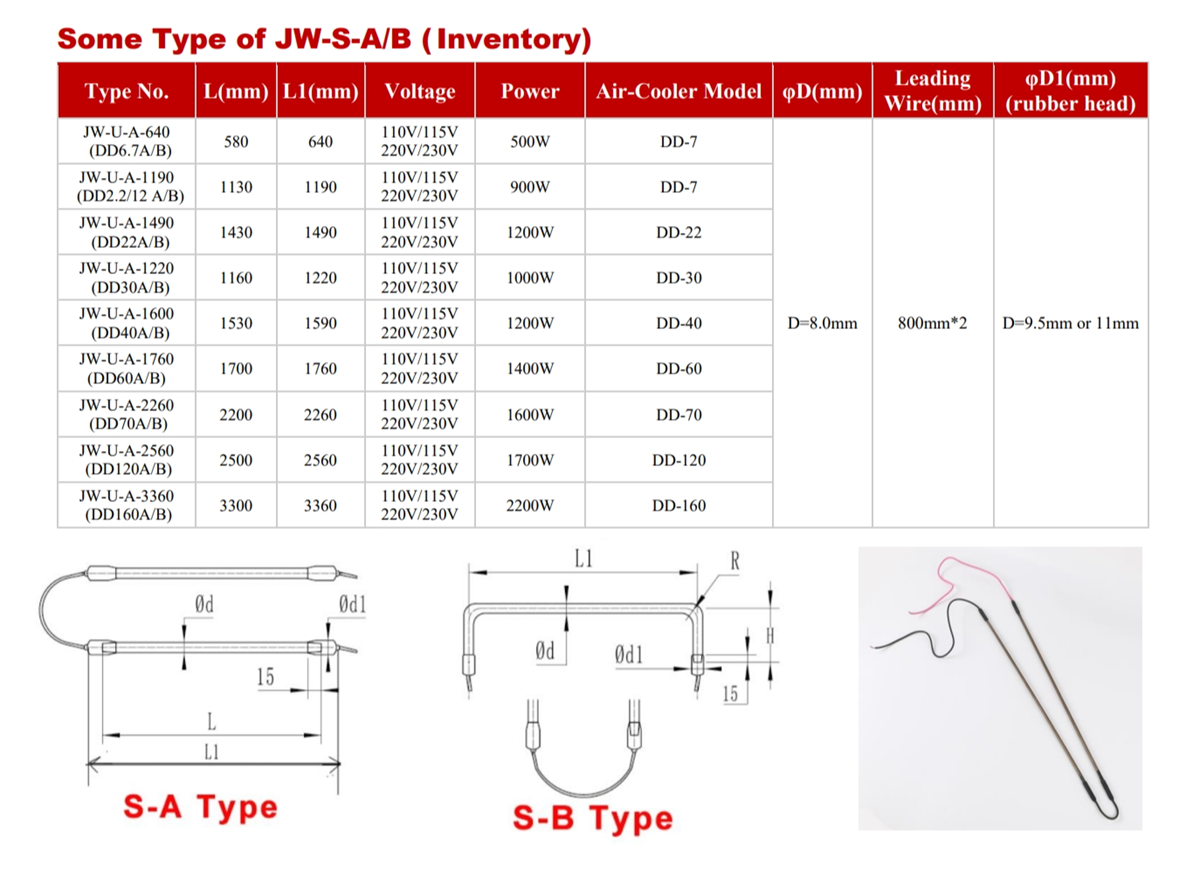

| The defrost tubular heater’s shape,size,power/voltage and the lead wire length can be customized as customer’s requirements,there is no any standard in our stock and need to be customized when place the order.

The defrost heating tube is about 300-400W per meter for defrosting,the shape of the defrsot heater we have straight,U shape,A-A type and other spcial shape. |

|

The surface temperature allowed by different pipe materials is not the same, such as 304 stainless steel 450-500 degrees, 321 stainless steel 700 degrees below, 310S stainless steel 900 degrees below; The same material and power, the different surface temperature of the medium is not the same, 304 stainless steel boiling water, the surface temperature of the water boiling tube is about 106 ° C, and the heating air air temperature can be about 450 ° C, the temperature of the heating cast aluminum is recommended to be used below 380 ° C, and the temperature is high aluminum will deform and even melt; Under the same material and medium, the electric heating tube with high power has a fast heating speed and high temperature.

The defrost heating tube processing needs materials including steel pipe, filler, electric heating wire, lead rod, sealing glue, high temperature wire and so on. We make the resistance wire into spiral shape according to the production single wire winding machine to ensure uniform winding distance. Weld the lead rod and the resistance wire, and fill the magnesia powder with a filler. The tube is compressed after filling the powder. We use the pipe shrink machine to compress and form, tighten the resistance wire and magnesium oxide powder to make it dense, ensure the insulation between the electric heating wire and the air, and the center position does not deviate and touch the pipe wall. And then bend it into the shape the customer wants.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314