Product Paramenters

| Porduct Name | Defrosting Parts GL Braided Heating Wire Factory |

| Insulation Material | Silicone rubber |

| Wire diameter | 2.5mm,3.0mm,4.0mm,etc. |

| Heating length | customized |

| Lead wire length | 1000mm,or custom |

| Color | white,red,yellow,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

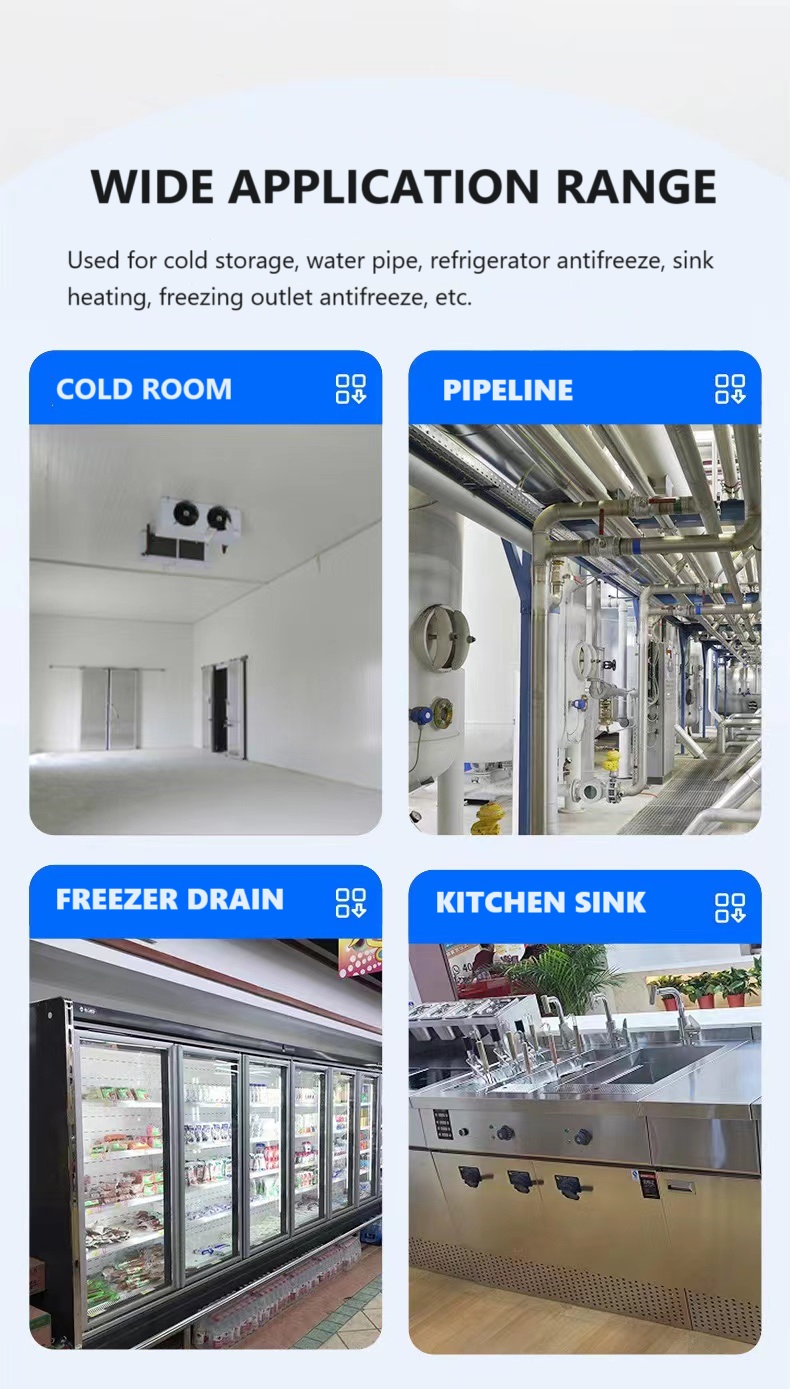

| Use | defrost heating wire |

| Certification | CE |

| Package | one heater with one bag |

|

JINGWEI heater is the braid heating wire factory,the picture products wire diameter is 3.0mm with fiberglass braid,the wire heater length and power can be customized as client’s requirements,lead wire length is 1000mm.The wire diameter can be choosed 2.5mm,3.0mm,3.5mm,and 4.0mm.The wire surface can also be braided aluminum or stainless steel. The defrost wire heater heating part with lead wire connector can be seal with rubber head or double-wall shrinkable tube,you can choose according to your own use needs. |

|

Product Configuration

Braided heating wire is based on the original silicone rubber heating wire to add glass fiber braid layer, aluminum braid layer and stainless steel braid layer, uniform temperature, high thermal efficiency, mainly by alloy heating wire and silicone rubber high temperature edge sealing cloth. The silicone heating wire has the characteristics of fast heating speed, uniform temperature, high thermal efficiency and good toughness. The glass fiber wire is wrapped with a resistance alloy wire or a single (multiple) resistance alloy wire as the core wire, and the outer layer is coated with a silicone /PVC edge layer of heating wire. Silicone heating wire has excellent heat resistance. It can be used for a long time at 150 ° C with almost no performance change. It can be used continuously for 10,000 hours at 200℃. Heating, mixing and insulation of pipes, tanks, towers and tanks for industrial equipment in the presence of wet and non-explosive gases can be wound directly on the surface of the part being heated.

Product Feature

1. Heating wire material: Constantan, Constantan, zinc white copper, nickel-chromium or copper-nickel alloy;

2. Hot wire structure: silicone single core hot wire, silicone multi-core hot wire, silicone single core spiral hot wire;

3. Internal winding process of the hot wire: heating wire is wound on the glass fiber;

4. Product testing standards: UL758 related standards for hot-wire;

5. Product bending test: more than 5000 times, no abnormal (test according to UL, IEC test standards);

6. Product winding test: more than 25,000 times, no abnormal (test according to UL, IEC test standards).

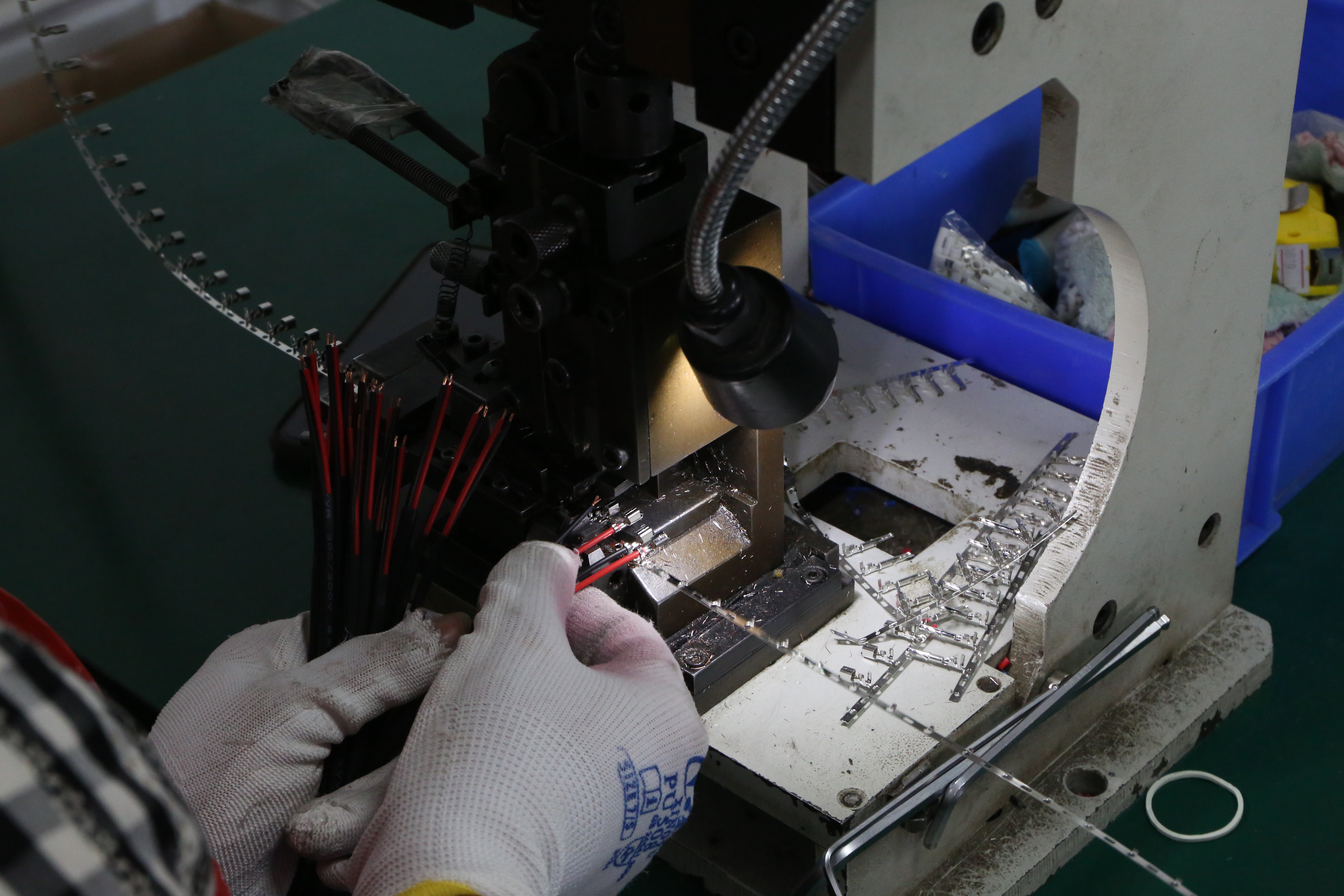

Factory Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314