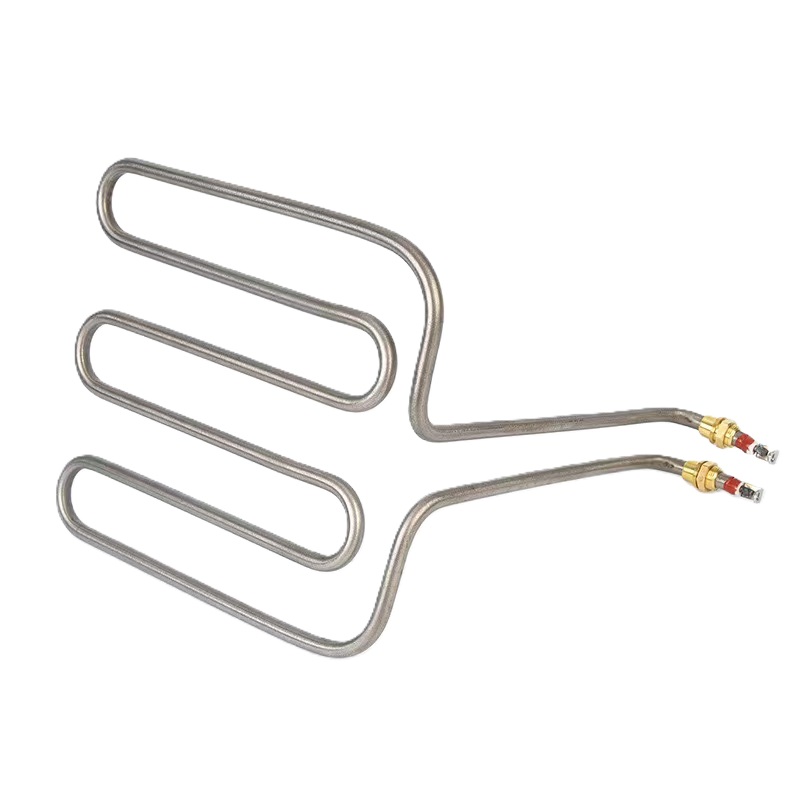

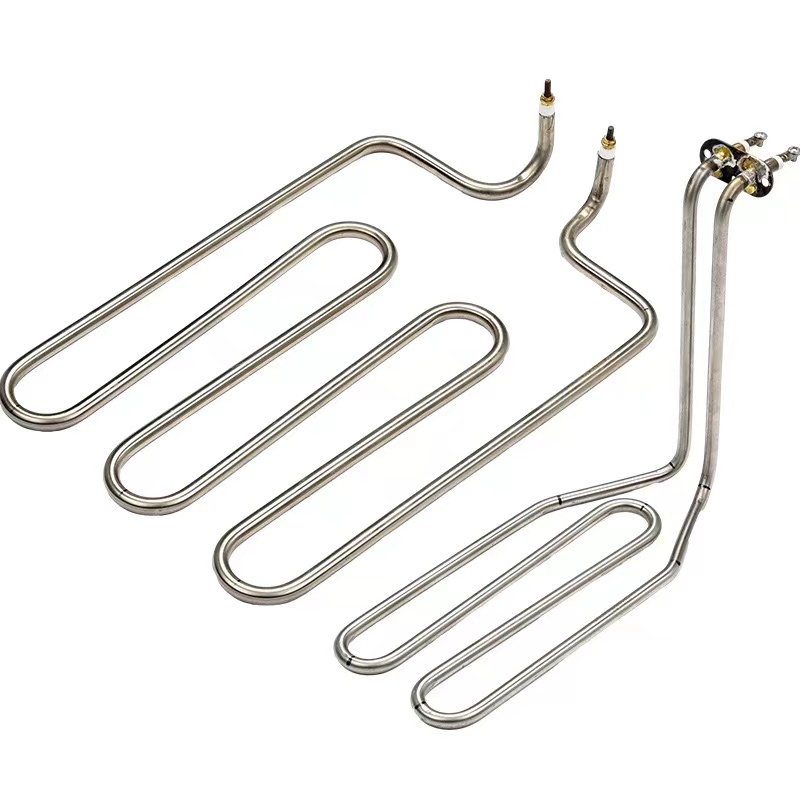

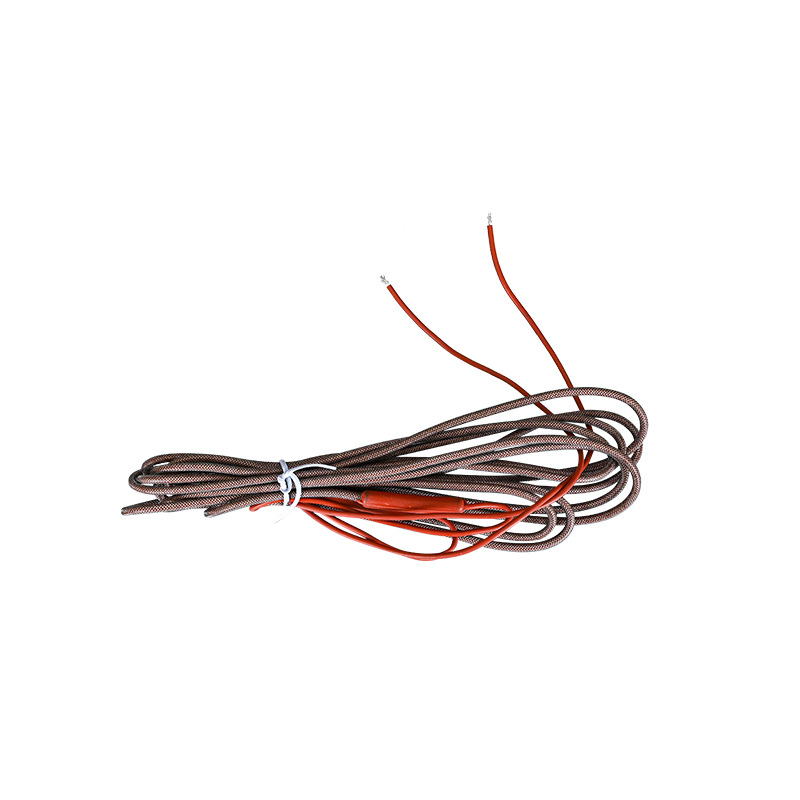

The deep oil fryer tube heating element is a key component in boiler or furnace equipment, its main function is to efficiently convert electrical energy into heat energy, so as to achieve accurate control of oil temperature. As one of the core components of the entire frying equipment, the role of the oil fryer heating element is crucial, which directly determines whether the oil temperature can be stable to reach the required cooking temperature, which in turn affects the taste and quality of food.

Specifically, the main task of the deep oil fryer tube heating element is to heat the oil pan to ensure that the oil temperature can be uniformly raised and maintained within an appropriate range. This process requires highly precise temperature control to avoid oil deterioration or food burning due to excessive temperature, but also to prevent the temperature too low to meet the frying needs. To achieve this,deep oil fryer heating tubes are usually made of high-quality metal materials that have good thermal conductivity and high temperature resistance, and can remain stable during long working periods.

In terms of heating principle, the deep oil fryer tube heating element generates heat through the current flowing through the metal tube body, and this electric heating conversion method has the characteristics of high efficiency and fast. When the current passes through the heating tube, the metal tube will rapidly heat up and transfer the heat to the surrounding oil, so that the oil temperature gradually increases until it reaches the ideal temperature range suitable for frying food. In addition, modern fryers may also be equipped with intelligent temperature control systems to further optimize heating efficiency and safety, ensuring that the equipment is more reliable during use.

| Porduct Name | Electric Deep Oil Fryer Tube Heating Element |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

| Shape | Customized |

| Resistant voltage | 2,000V/min |

| Insulated resistance | 750MOhm |

| Use | Deep Oil Fryer Heating Element |

| Tube length | 300-7500mm |

| Terminal | Customized |

| Approvals | CE/ CQC |

| Company | Factory/supplier/manufacturer |

|

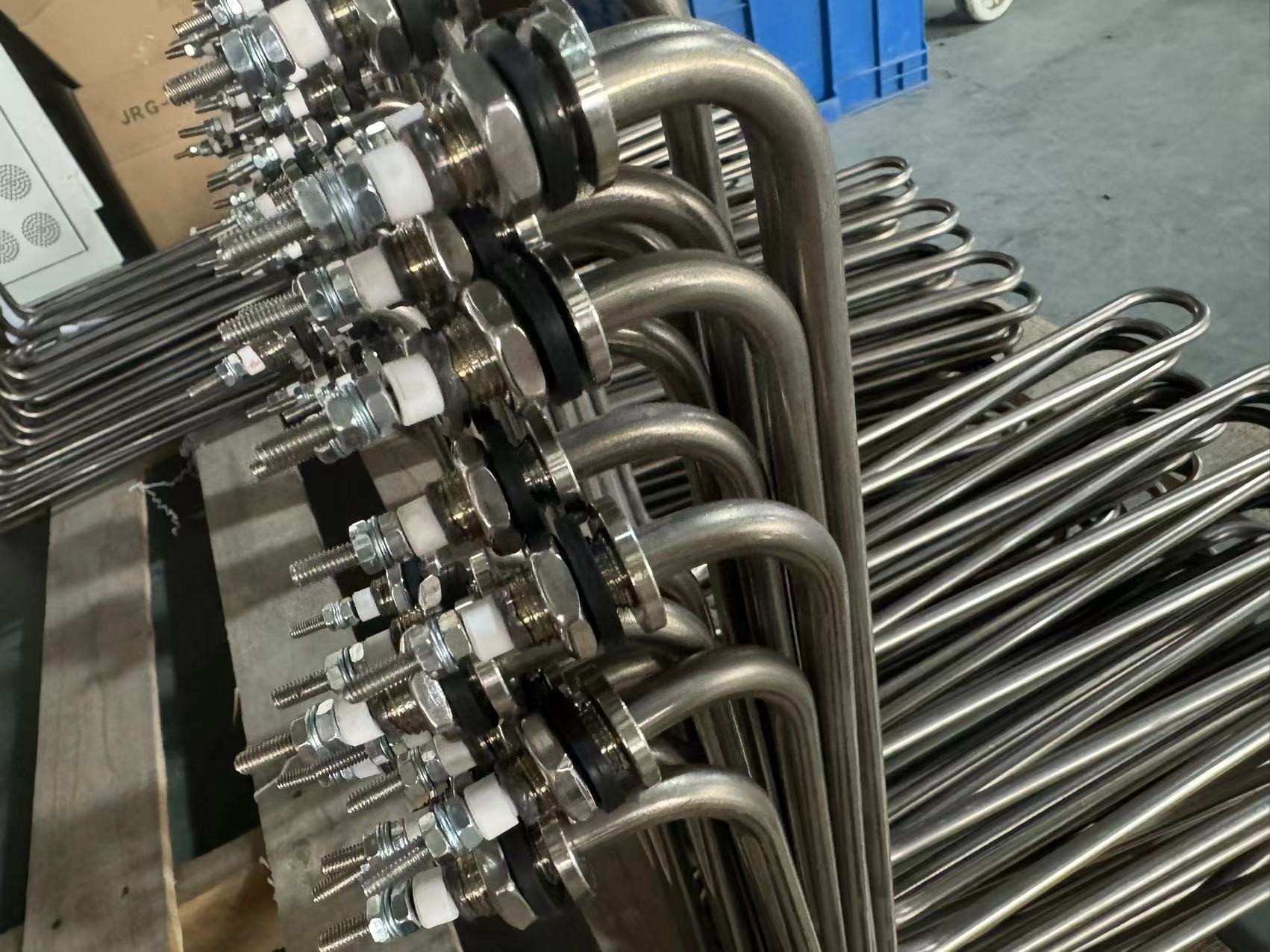

JINGWEI heater is the professional oil deep fryer tube heating element manufacturer,we have more than 25 years on the electric stainless steel heating tube customized.The power of oil fryer tube heating element can also be customized as requirements.The tube head we'll usually use the flange,flange material we have stainless steel or copper. |

|

1. Exposed heating pipe: the deep oil fryer tube heating element directly immersed in the oil, high heating efficiency, but need to clean the oil dirt regularly.

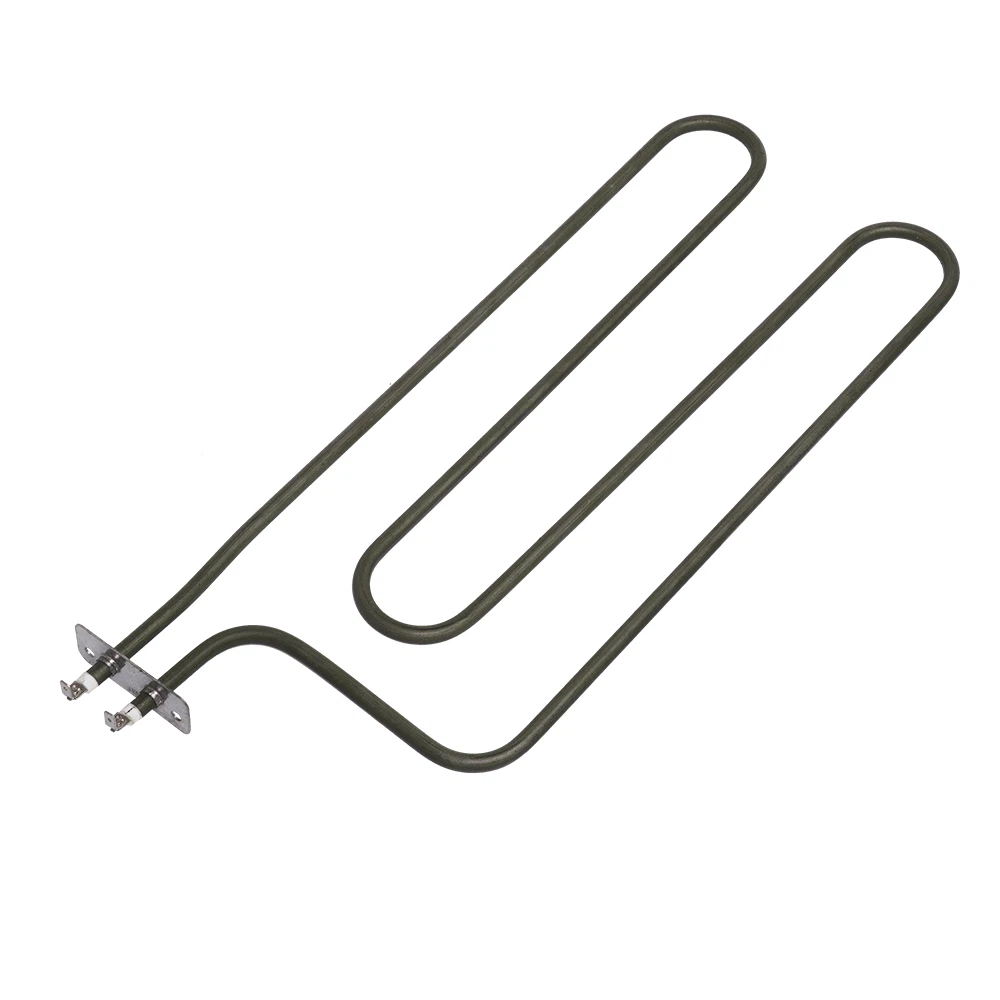

2. Hidden heating tube: wrapped in a metal layer, not easy to accumulate scale, but the heating speed is slightly slower, common in high-end models.

3. Quartz heating tube: used in some commercial fryers, high temperature resistance but more brittle, need to prevent collision.

1. Household area

*** The oil deep fryer heating element used for fries, chicken wings, churros, tempura and other household food.

*** Commonly found in small bench deep fryers (capacity 1-5 liters), the power is usually 800-2000W.

*** Deep oil fryer element heating tube mostly adopts stainless steel or hidden design, easy to clean.

2. Catering commercial field

*** Fried chicken, hamburger restaurants (such as KFC, McDonald's) use high-power commercial fryers (power 3-10kW), heating pipes need to be high temperature resistant, corrosion resistant (stainless steel).

*** Continuous operation requires rapid heating and strong stability of the heating tube.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314