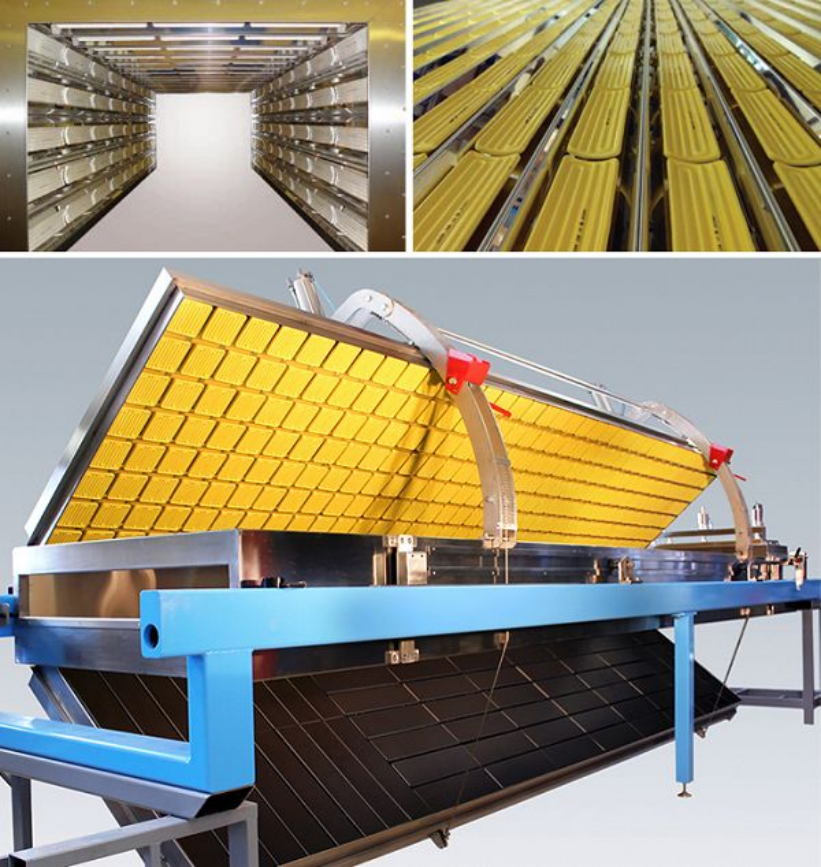

| Porduct Name | Electric Infrared Ceramic Heater Plate |

| Material | Ceramic |

| Voltage | 12V-480V,can be customized |

| Wattage | 125-1500W or customized |

| Shape | Flat/Curved/Bulb |

| Resistant wire element | Ni-Cr or FeCr |

| Useful wavelength range | 2 to 10 um |

| Average operating life | Up to 20,000 hrs depending on conditions |

| Internal thermocouple | K or J type |

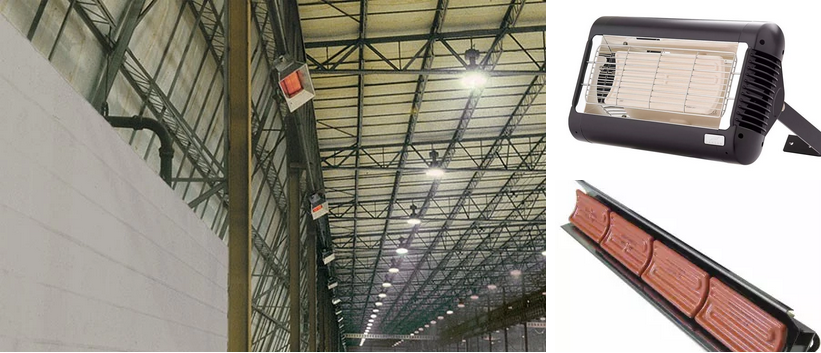

| Use | Infrared Ceramic Heater |

| Cold areas | Depends on length and diameter 5-25mm |

| Recommended radiation distance | 100mm to 200mm |

| Package | one heater with one box |

| Color | black,white,yellow |

|

The standard size of Infrared Ceramic Heater 1. 60*60mm 2. 120mmx60mm 3. 122mmx60mm 4. 120mm*120mm 5. 122mm*122mm 6. 240mm*60mm 7. 245mm*60mm With K or J type Thermocouple |

|

Ceramic infrared heaters consist of resistive thermal conductors fully embedded in appropriate ceramic materials. Because it is fully embedded in the ceramic, the energy generated by the thermal conductor can be transmitted to the material around it, which both prevents the thermal conductor from overheating and extends its service life. The material used to embed the thermal conductor must be insulated and have good absorption and radioactivity within the set range of infrared radiation. To meet this requirement, ceramic infrared heaters can be made in different geometric shapes.

The main body of the ceramic infrared heater pad is ceramic, which uses a part of the surface as a radiant surface and integrates a heating coil. For ceramic infrared heaters, a thermocouple can also be fixed in an adjacent position to the thermal conductor.

1. Infrared Ceramic Heater plate is not waterproof structure, so do not contact with oil, water and plastic particles during storage and installation to prevent leakage.

2. Before installation, check whether the installation position is consistent with the specifications of the electric Infrared Ceramic Heater and whether the use voltage is consistent.

3. When installing, the Infrared Ceramic Heater must be closely fitted with the heated body, and the surface of the heated body should be flat and complete, without uneven phenomenon.

4. When using Infrared Ceramic Heater Pad, avoid hard knocking or collision with hard objects to cause ceramic tile breakage, alloy resistance wire exposed affect the operation life.

5. If the Infrared Ceramic Heater plate is found to produce a scorched black color on the surface after use, it indicates that the heat and heat dissipation of the heated body are unbalanced, and should be adjusted in time to prevent burning through.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314