Product Configuration

Evaporator coil defrost heater is an important component used in refrigeration equipment, air conditioning and other fields. The defrost heater tube is made of stainless steel tube, and the spiral electrothermal alloy wire (nickel chromium, iron chromium alloy) is uniformly distributed along the central axis of the tube. The void is filled with modified magnesia with good insulation and thermal conductivity, and the two ends of the tube are sealed with silica gel or ceramic.The tube material have stainless steel 304,stainless steel 316,stainless steel 310S.

Evaporator defrost heating tube core function:

1. Automated frost control

The evaporator coil defrost heater tube is heated by electric heating wire (power: 300-400W/M), and regularly melts the frost layer on the surface of the evaporator to avoid excessive ice thickness affecting the refrigeration efficiency.

2. Maintain the cooling system stability

In a low temperature environment (such as winter), the auxiliary heating compensates the evaporator temperature to prevent frequent compressor start and stop or abnormal refrigerant circulation caused by low ambient temperature .

Product Paramenters

| Porduct Name | Evaporator Coil Defrost Heater Pipe |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

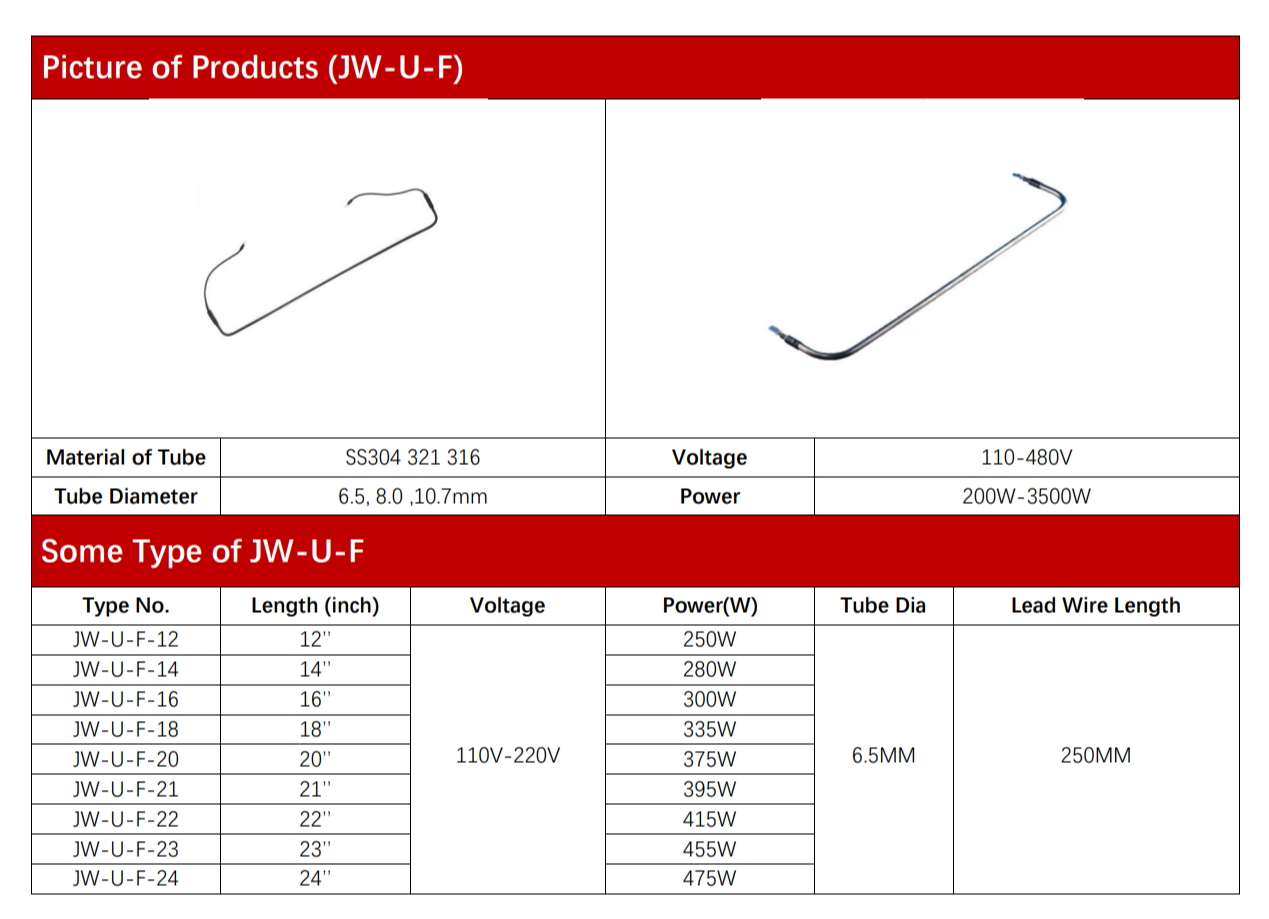

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Defrost Heater Element |

| Tube length | 300-7500mm |

| Lead wire length | 700-1000mm (custom) |

| Approvals | CE/ CQC |

| Company | Manufacturer/supplier/factory |

|

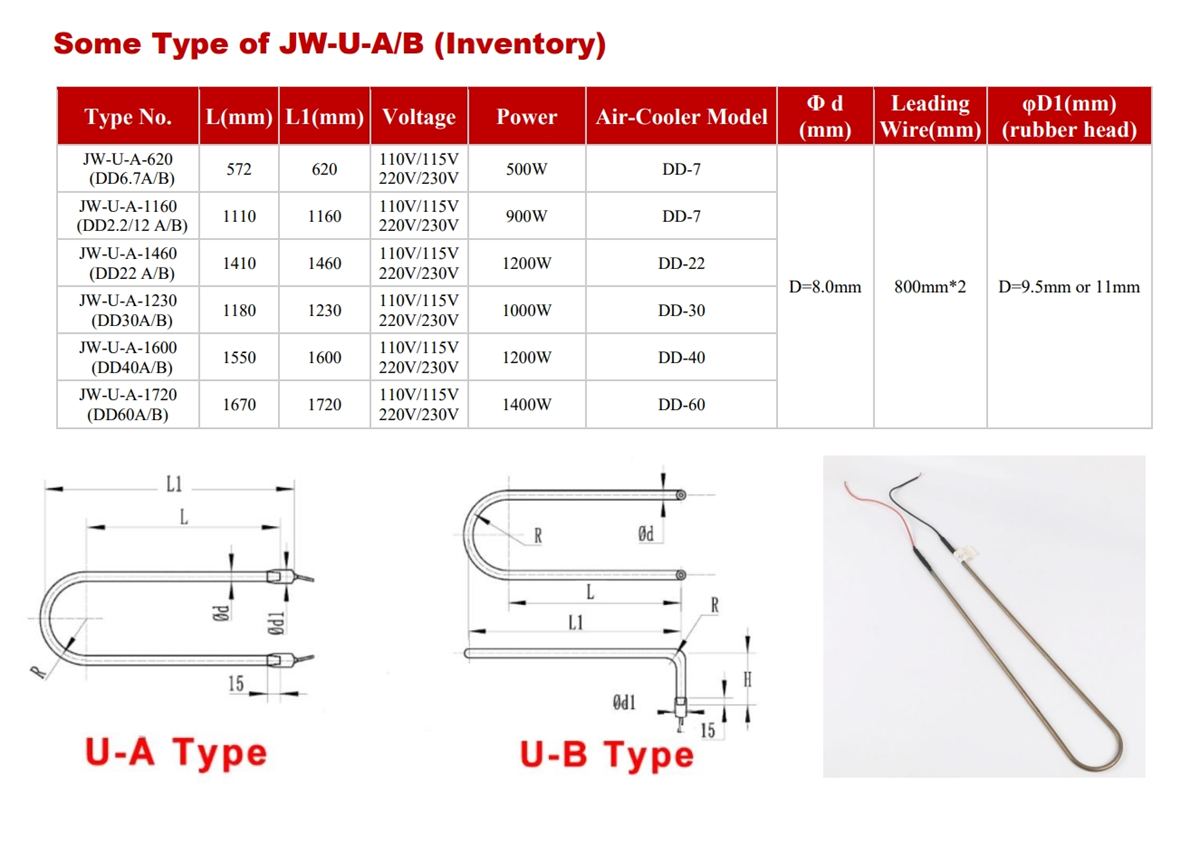

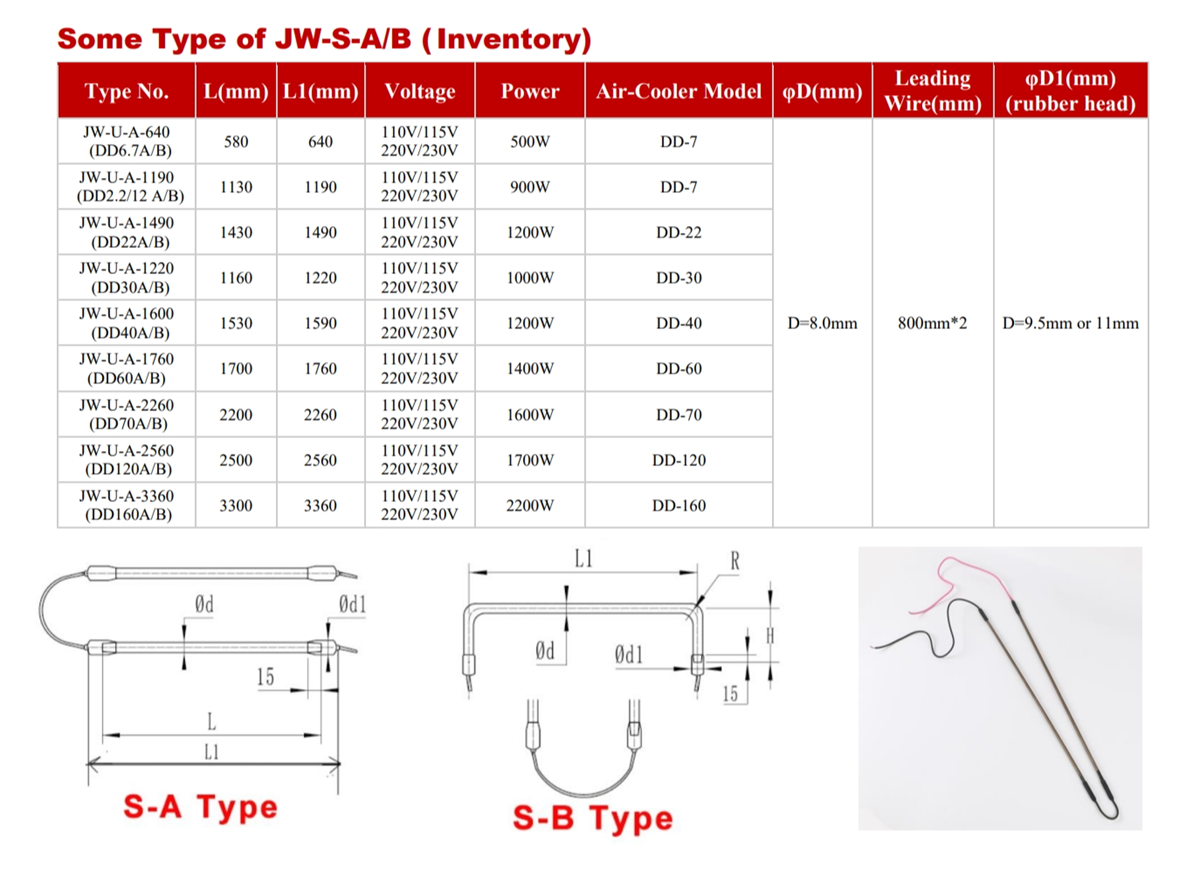

The evaporator coil defrost heater tube is used for the air cooler defrosting,picture shape of tubular defrost heating element is A-A type (double straight tube ),tube length custom is following your air-cooler size,our all defrost heater can be customized as required. The evaporator coil defrost heater tube diameter can be made 6.5mm or 8.0mm,the tube with lead wire part will be sealed by rubber head.And the shape can also be made U shape and L shape.Power of defrost heater tube will be produced 300-400W per meter. |

|

Defrost Heater for Air-cooler Model

Position of Evaporator Defrost heater in refrigerator

Air-cooled refrigerator location

1. Around the freezer evaporator

In air-cooled refrigerators, the evaporator defrost heating tube is usually located on the surface or bottom area of the evaporator in the freezer chamber. After the freezer drawer needs to be removed, the heating tube can be found near the evaporator coil, and its installation position is fitted to the evaporator (gap ≤1mm) to achieve efficient frost .

Straight-refrigerated refrigerator location

1. Refrigerator back panel

The evaporator of the direct cooling box is usually a metal backplane on the back wall of the cold room (the surface is prone to frost). The defrost heating tube heater is directly embedded in the interlayer of the backplane or close to its back, and the frost layer is melted by heat conduction .

Product Application

1. cold storage cooling fan : defrost heater tube used for evaporator defrost, prevent frost accumulation affect refrigeration efficiency ;

2. cold chain equipment : U shape defrost heater Maintain the constant temperature environment of refrigerated truck and display cabinet to avoid frost resulting in temperature control failure ;

3. industrial refrigeration system : defrost tube heater is integrated in the bottom of the water pan or condenser to ensure the continuous operation of the equipment

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314