The basic performance characteristics of aluminum electric heater

1. has a very high thermal efficiency, the overall temperature rise is fast, can effectively complete a variety of thermal processing behavior, to help businesses, manufacturers to efficiently complete all kinds of production and processing operations.

2. has a very excellent mechanical properties and physical properties, users do not need to worry about such devices by the outside world interference, because it has a very excellent anti-electromagnetic field interference performance.

3. in the process of operation is very stable and reliable, the equipment is very safe and efficient operation, can be used for a long time, in the later operation process does not require excessive investment in human and material resources.

4. has a strong corrosion resistance, high temperature resistance, wear resistance and other properties, the price is also relatively affordable, diversified performance, the use of a wide range.

What are the daily maintenance measures for liquid heaters?

1. first of all, check whether the power supply voltage of the use site is consistent with the rated voltage of the product, if different, should be equipped with the same power supply voltage as the rated voltage of the product.

2. In order to ensure safety, remember to use the power equipment shell to reliable grounding.

3. electric heater products exist for more than three months and then use, should be intermittently energized under the permitted conditions to dry themselves, heating ten minutes power off for half an hour, three to four times in a row to discharge the moisture inside the electric heating element.

4.electric heater during storage should pay attention to moisture corrosion, stored in a well-ventilated place.

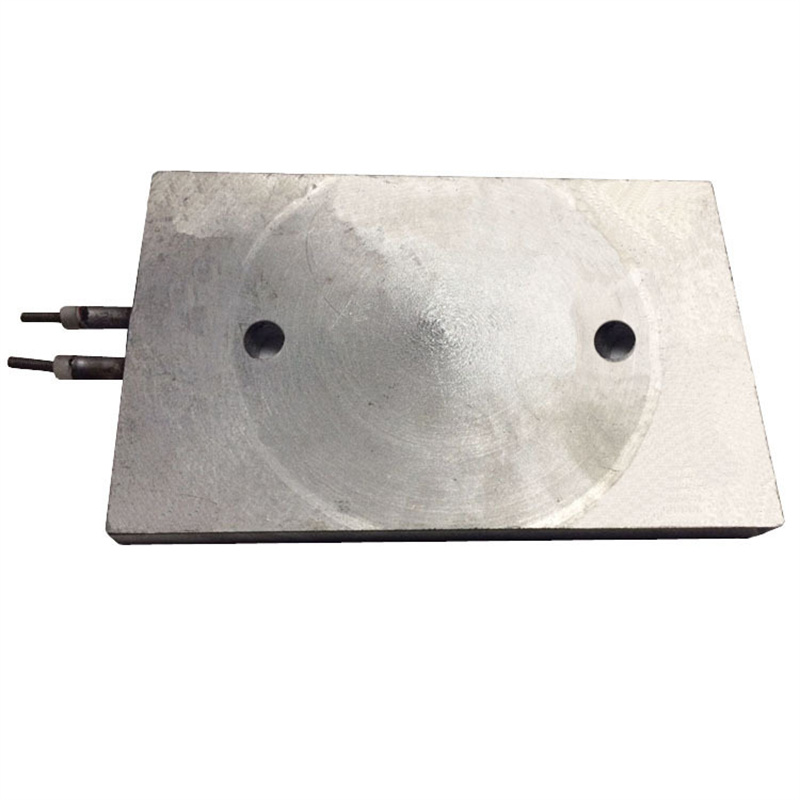

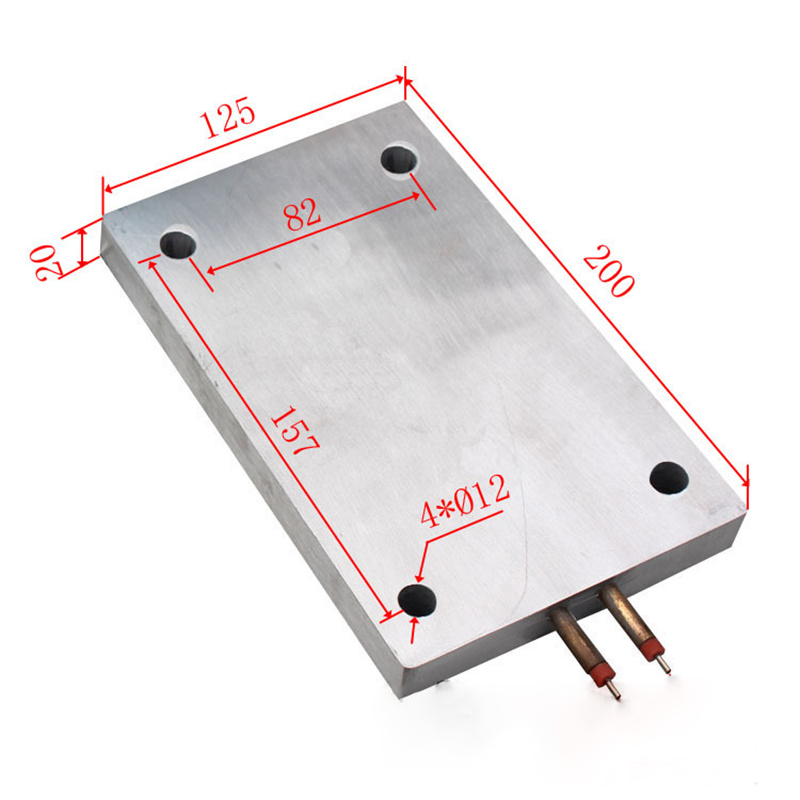

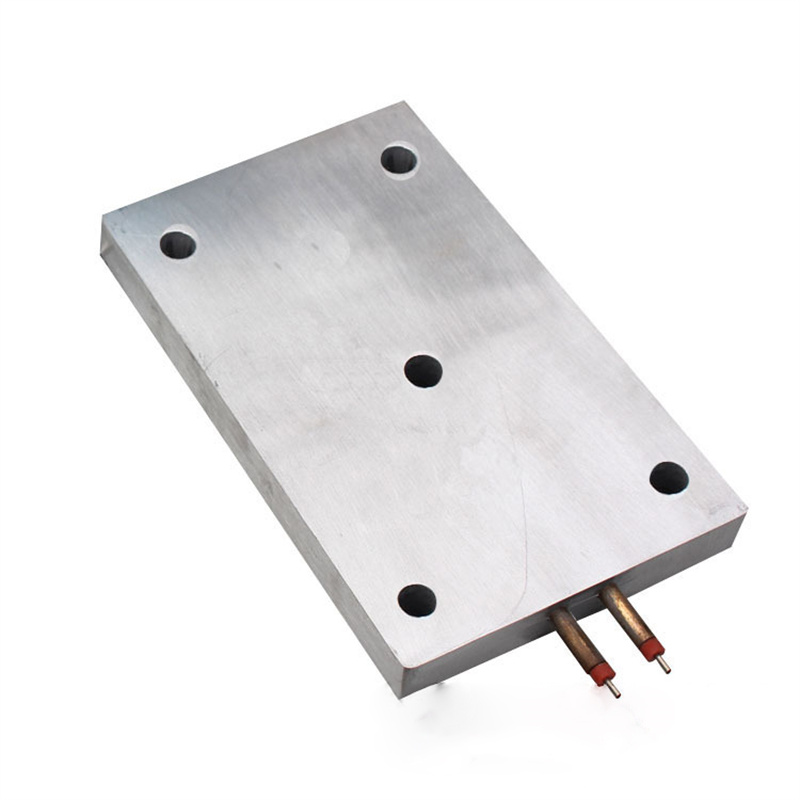

Aluminum plate electric heating plate has excellent anti-mechanical strength performance, excellent insulation and pressure resistance, moisture-proof, easy processing and other characteristics, small temperature difference, and many other characteristics, in the mechanical equipment, aerospace, military, new energy and other fields, to solve the many low temperature caused by the trouble.

In addition in the parts and mold heating, wood and paper industry, automotive industry, mold manufacturing, plastic industry, binding has also been popularly used.