The working principle of the electric heating tube is that when there is a current in the high temperature resistance wire, the heat generated is transmitted to the surface of the stainless steel tube through the modified oxide powder, and then conducted to the heated part. This structure is not only advanced, high thermal efficiency, fast heating, and uniform heating, the product in the power heating, the tube surface insulation is not charged, safe and reliable use. We have more than 20 years of custom experience in stainless steel heating tubes, producing different kinds of electric heating tubes, such as defrost heating tubes , oven heating element, finned heating element, water immersion heating tubes, etc. Products are exported to the United States, South Korea, Japan, Iran, Poland, Czech Republic, Germany, Britain, France, Italy, Chile, Argentina and other countries. And has been CE, RoHS, ISO and other international certification. We provide perfect after-sales service and a quality guarantee of at least one year after delivery. We can provide you with the right solution for a win-win situation.

-

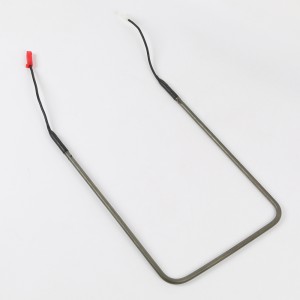

242044113 Refrigerator Freezer Defrosting Heater Element

Refrigerator Defrost Heating Element; part number 242044113.

Designed to fit specific Electrolux manufactured refrigerator models including Crosley, Frigidaire, Gibson, Kelvinator. -

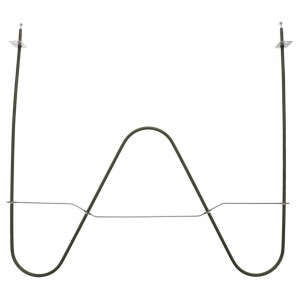

Refrigerator Assembly Part#218169802 Tubular Defrost Heater

The Tubular Defrost Heater assembly (part number 218169802) is for refrigerators.

Defrost heater assembly 218169802 melts frost from the evaporator fins during the automatic defrost cycle.

Safely store any food that could deteriorate while the power is off. Unplug the refrigerator before installing this part. Wear work gloves to protect your hands. -

220V SS304 Air Finned Tube Heater

The Finned Tube Heater specification can be customized as client’s requirements,Shape we have straight,U shape,M shape and other custom shapes.The finned heating tube is wound on the surface of the stainless steel electric heating tube to expand the heat dissipation surface and increase the heat dissipation speed, so as to effectively control the service life of the electric heating tube.

-

DG47-00038B Bake Element for Samsung Oven Tubular Heater

This Oven Tubular Heater part number is DG47-00038B,and it is the bake element for Samsung.The package is one heating tube with one bag,35pcs one carton.

-

Refrigerator Defrost Heater Wholesale&Manufacturer

The Refrigerator Defrost Heater can be customized as customer’s requirement,the length we have from 380mm to 560mm,the longest length can also be customized.The volatge will be 110V-230V,the power is 345W or custom.

-

U Type Defrost Tubular Heater Factory and Manufacturer

Defrost tubular element is used on the evaporators and refrigerating system which will defrost finned bodies. They are extremely flexible and used as a practical solution thanks to its capacity to form to the shapes of the various types of evaporator.

-

Good Quality Stainless Steel Electric Finned Air Tubular Heater

Electric Finned Air Tubular Heater is often directly used for bare dry burning in the air, its structure is in the stainless steel pipe into the heating wire, and in the gap part tightly filled with good thermal conductivity and insulation of the oxide powder, out of the terminal or direct high temperature lead. Finned strip heater has the characteristics of simple structure, high mechanical strength, can be bent into various shapes, high thermal efficiency, safe and reliable, easy installation, good mechanical strength, long service life and so on.

Air tubular heating tube can heat stationary or moving air, and can melt light metals and metal molds and various liquids.

-

China Factory Custtom Tubular Pizza Oven Heating Element

Pizza Oven Heating Element is made of high quality stainless steel, modified magnesium oxide powder, high resistance electrothermal alloy wire and other materials through advanced production equipment and technology. The use of modified magnesium oxide powder can make the surface load of the electric heating tube reach 7 watts/per square centimeter, which is 3 to 4 times that of ordinary components. The modified magnesium oxide powder can withstand high temperature up to 700℃ or even higher, so that the electric heating tube has better insulation performance and high heating efficiency, thus improving the service life of the electric heating tube. The annular heating rod also has the advantages of fast heating, uniform heating and good heat dissipation.

-

Fridge Parts Stainless Steel 304 Defrost Tubular Heating Element

Defrost Tubular Heating Element details can be customized as clien’s requirement.The heater size ,shape,power and voltage all can be designed.JINGWEI heater is a factory,we don’t have any standard heater,if you have any doubts on the heating element’s problem,you can contact us anytime.

-

China Manufacturer Air Finned Tubular Heater Elements

The winding Finned Tubular Heater Elements is a steel strip with a uniform winding width of 6 – 7mm on a smooth stainless steel heating tube with special equipment. The thickness of such a winding finned electric heating tube is pipe diameter + steel strip *2. Compared with the ordinary element, the heat dissipation area is expanded by 2 to 3 times, that is, the surface power load allowed by the fin element is 3 to 4 times that of the ordinary element. Due to the shortening of the length of the component, the heat loss of itself is reduced, and it has the advantages of fast heating, uniform heating, good heat dissipation performance, high thermal efficiency, long service life, small size of the heating device and low cost under the same power conditions.

-

China Stainless Steel Heating Element for Microwave Oven

The electric heating element of the oven heating tube is a metal tube as the shell (iron, stainless steel, copper, etc.), and the spiral electric thermal alloy wire (nickel chromium, iron chromium alloy) is uniformly distributed along the central axis of the tube. The void is filled with the crystalline magnesia with good insulation and thermal conductivity, and the two ends of the tube are sealed with silicone and then processed by other processes. This oven grill heating element can heat air, metal molds and various liquids. The oven heating tube is used to heat the fluid by forced convection. It has the characteristics of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, easy installation, long service life and so on.

-

High quality finned tubular Heating element Heater Tube

Heating tube is a metal tube for the shell, along the tube center axially evenly distributed spiral electric heating alloy wire (nickel-chromium, iron-chromium alloy) gap filling compacted with good insulation and thermal conductivity of magnesium oxide sand, the two ends of the tube mouth with silicone or ceramic seal.