Product Paramenters

| Porduct Name | Infrared Ceramic Pad Heater |

| Material | Ceramic |

| Voltage | 12V-480V,can be customized |

| Wattage | 125-1500W or customized |

| Shape | Flat/Curved/Bulb |

| Resistant wire element | Ni-Cr or FeCr |

| Useful wavelength range | 2 to 10 um |

| Average operating life | Up to 20,000 hrs depending on conditions |

| Internal thermocouple | K or J type |

| Use | Infrared Ceramic Heater |

| Cold areas | Depends on length and diameter 5-25mm |

| Recommended radiation distance | 100mm to 200mm |

| Package | one heater with one box |

| Color | black,white,yellow |

|

The standard size of Infrared Ceramic Heater 1. 60*60mm 2. 120mmx60mm 3. 122mmx60mm 4. 120mm*120mm 5. 122mm*122mm 6. 240mm*60mm 7. 245mm*60mm With K or J type Thermocouple |

|

Product Configuration

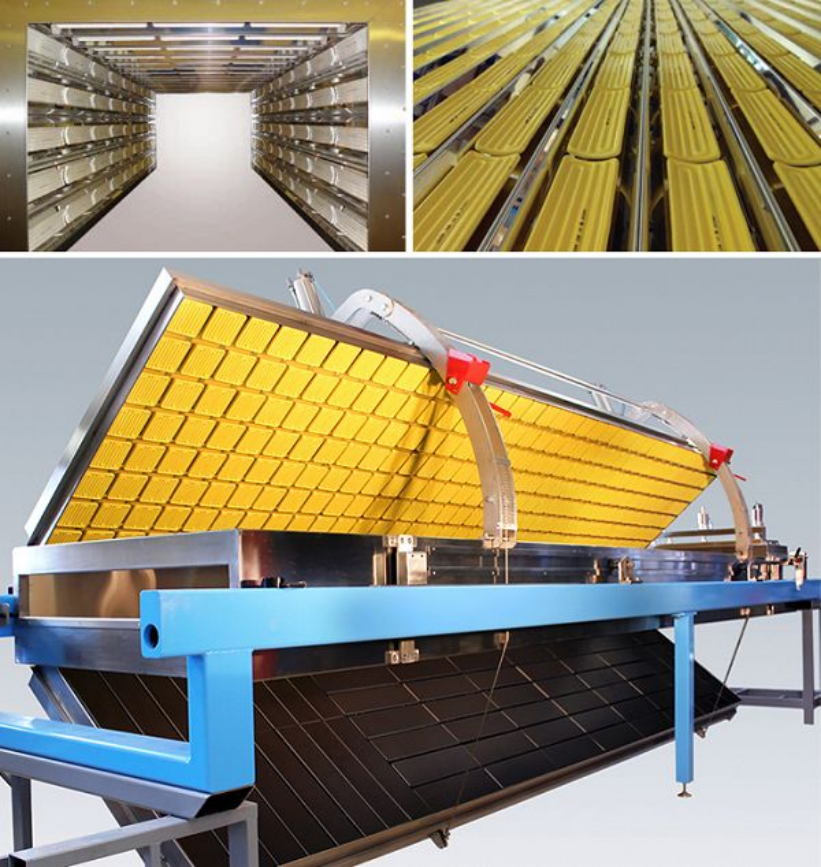

Infrared Ceramic Pad Heater is cast by ceramic injection molding process, which is characterized by ultra-thin heating body. Compared to Elatein's other series of plate radiators, the height of the FSF is reduced by about 45%, which saves a lot of installation space and is suitable for machine modifications.

The maximum operating temperature of Infrared Ceramic Pad Heater is 720℃, the maximum surface average thermal power density is 64KW/m², there are 4 specifications and sizes to choose from, heating power range from 60W to 1000W.

Product Features

Infrared Ceramic Heater plate structure: ceramic electric heating plate is made of high radiation glaze layer, ceramic with good thermal shock performance as the matrix, and high-quality electric heating wire is sintered at a time. Their compositions are as follows:

1. Matrix: composed of ceramic material with good thermal shock;

2. Heating: made of high quality nickel-chromium alloy wire;

3. Glaze layer: It is composed of metal oxide raw materials with good radiation performance and put appropriate additives to improve the radiation intensity and enhance the adaptability of the glaze.

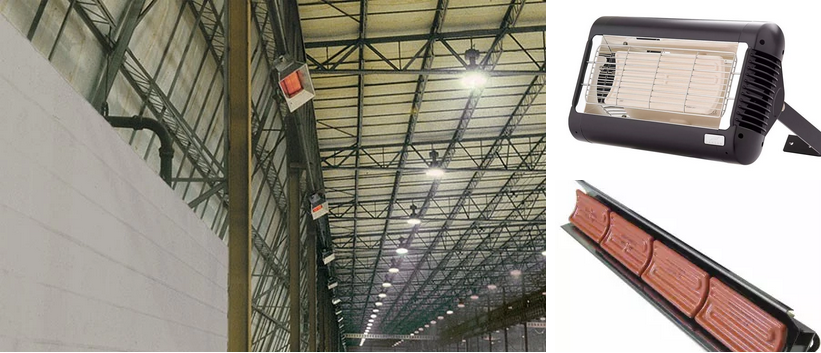

Product Applications

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314