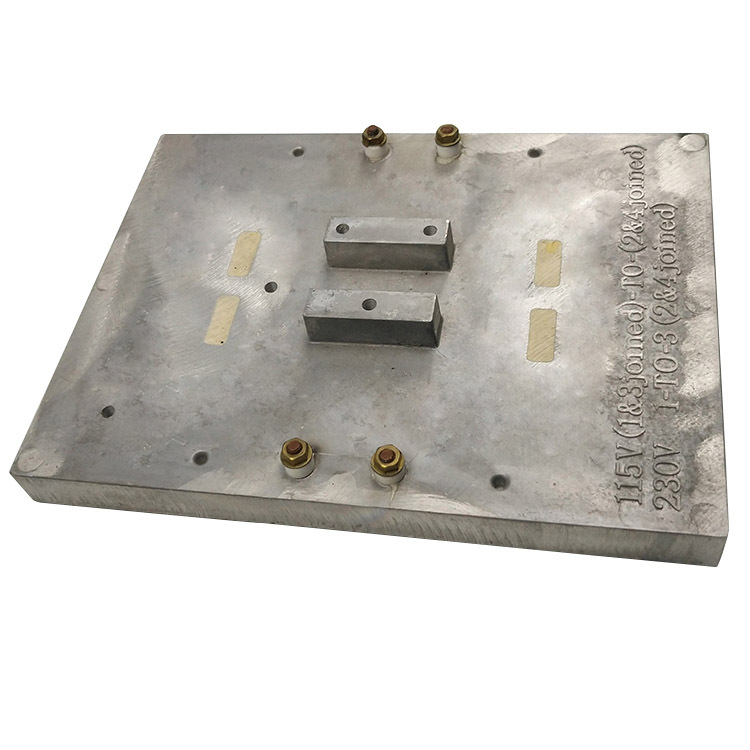

First. The advantages of aluminum casting heating plate:

1. Good corrosion resistance: Cast aluminum heating plates have superior corrosion resistance, allowing them to operate stably in various harsh working environments, especially suitable for medium heating in corrosive environments.

2. Excellent thermal conductivity: Cast aluminum heating panels have good thermal conductivity, allowing heat to be transferred quickly and evenly, resulting in high thermal efficiency and reducing energy waste.

3. High-quality workmanship: The aluminum casting heating plate is made through multiple fine processing procedures and inspections, resulting in a smooth and even surface with high gloss and flatness, which can reduce local temperature differences and promote even heating.

4. Long service life: Cast aluminum heating panels have a longer service life than conventional heating panels, which can withstand long-term use and harsh environments, thereby reducing maintenance and replacement costs.

Second. Disadvantages of Cast Aluminum Heating Plates

1. Configuration is troublesome: Cast aluminum heating panels require additional power equipment to be configured, and the installation cost is high.

2. Overheating: The heating area of the cast aluminum heating plate is larger, and heating improperly can cause overheating or uneven heating, which can damage or affect the quality of the heated material.

3. The temperature cannot be too high: The maximum operating temperature of cast aluminum heating plates is limited, generally not exceeding 400℃. Attention should be paid to temperature control during use to avoid overheating damage.

Third. The Application Value of Cast Aluminum Heating Plates

Cast aluminum heating plates are widely used in industrial heating applications, such as plastic processing, candle production, packaging, and textile industries. Among them, in the plastic processing industry, cast aluminum heating plates have become an indispensable heating method, which can improve production efficiency, guarantee product quality and production safety.

Fifth. Precautions

When using cast aluminum heating plates, the following points should be noted:

1. Do not subject the heating surface to excessive force, or it may be damaged.

2. When cleaning the heating plate, please pay attention to the method and avoid using strong irritants and corrosive cleaning agents.

3. Be sure to adjust and control the temperature of the heating plate to avoid overheating and damage.

4. The wiring of the cast aluminum heating plate should be correct to avoid accidents caused by poor welding quality.

5. Regularly check the insulation of the cast aluminum heating plate to ensure safe use.

Conclusion:

Cast aluminum heating plates have superior corrosion resistance and heat transfer properties, as well as a long service life. They are widely used, but care must be taken when using them to ensure safe and stable production, including temperature control and load on the heating area.

Post time: Nov-18-2024