When using cold storage cold air machines, refrigeration and freezing cold storage display cabinets, etc., there will be a phenomenon of frost formation on the evaporator surface. Due to the frost layer, the flow channel will become narrower, the wind volume will decrease, and even the evaporator will be completely blocked, seriously impeding air flow. If the frost layer is too thick, it will make the cooling and cooling effect of the refrigeration device worse, increase power consumption, and some refrigeration devices will use defrost heater tube to defrost periodically.

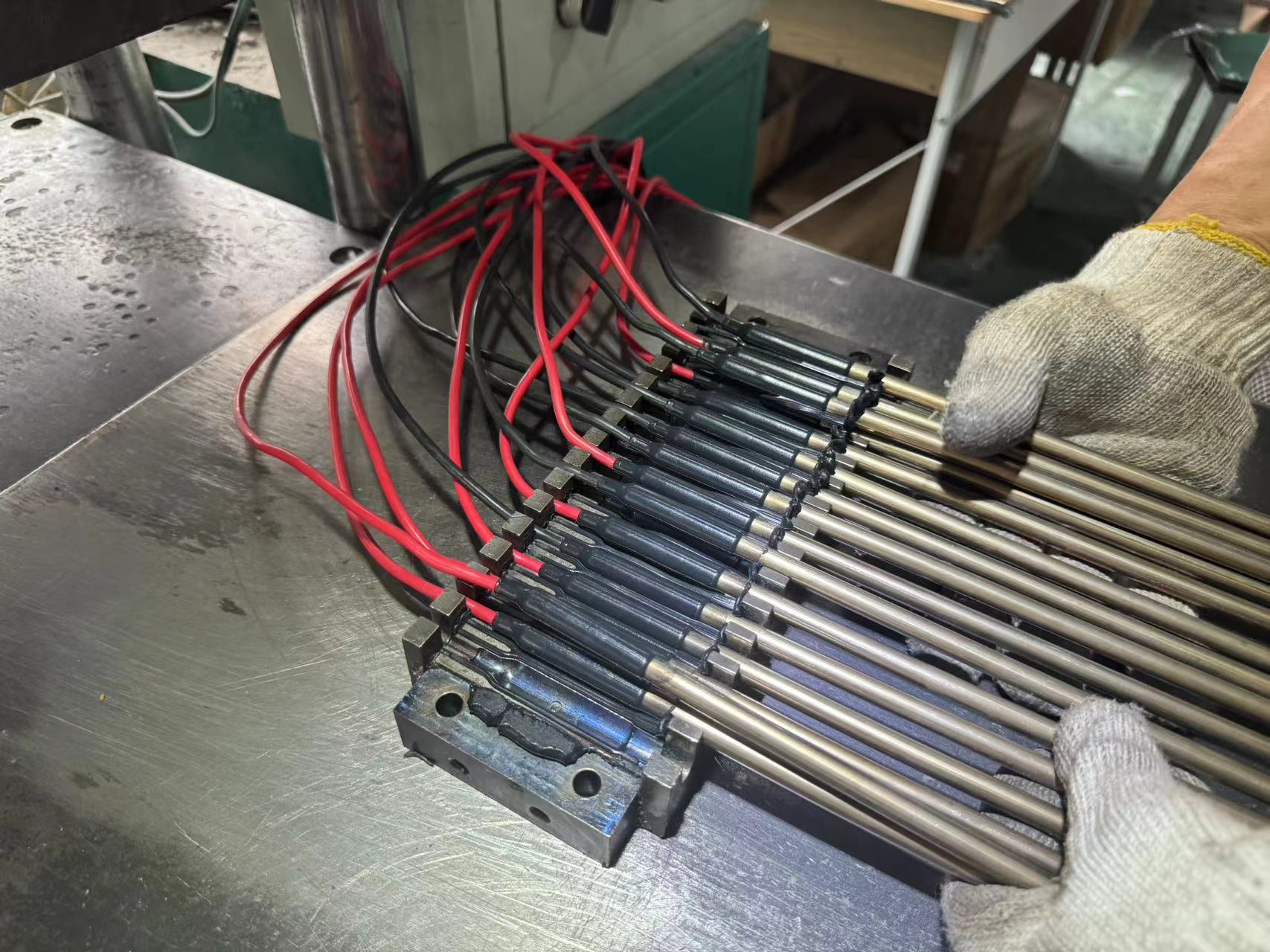

Electrical defrost heater tube is a method of defrosting by heating the frost layer attached to the surface of the equipment using the defrost heater tubes arranged inside the equipment. This type of defrost heater tube is a type of metal tube-shaped electric heating element, also called defrosting heating tube or defrost heater tube. The electric defrost heater tube is an electric heating element in which the metal tube serves as the shell, the alloy heating wire as the heating element, and the end terminals (wires) are provided. The insulating medium of magnesium oxide powder is filled densely in the metal tube to fix the heating element.

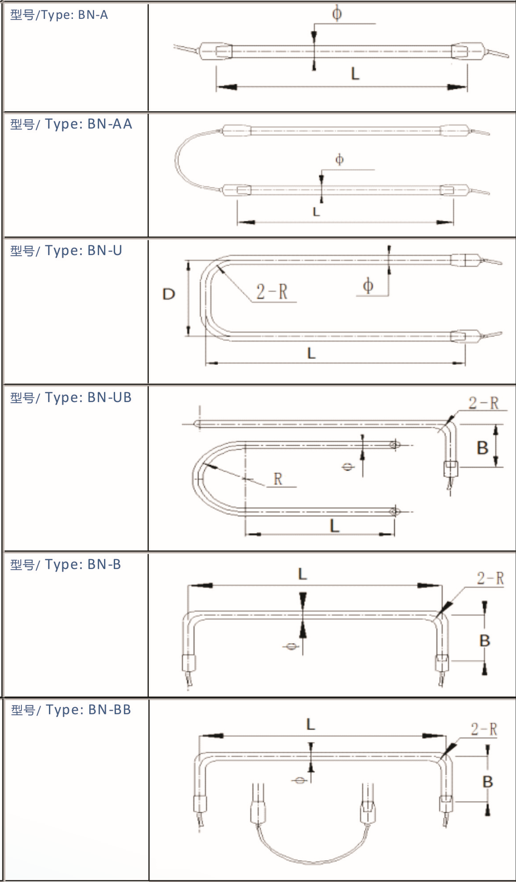

Due to the characteristics of cold storage equipment, such as high humidity and low temperature indoors, frequent cold and hot shocks, defrosting heating tubes are generally based on tube-shaped electric heating elements, using high-quality modified magnesium oxide as filler and stainless steel as the shell. After shrinking, the connection end is sealed with a special rubber pressed mold, so that the electric heating tube can be used normally in cold storage equipment. It can be bent into any shape according to user needs and conveniently embedded in the ribs of the cold air machine or the surface of the evaporator of the cold cabinet or the bottom of the drain tray, etc. for defrosting. The basic structure of the defrost heater is as follows:

a) Lead rod (line) : is connected with the heating body, for components and power supply, components and components connected with the metal conductive parts.

b) Shell pipe: generally 304 stainless steel, good corrosion resistance.

c) Internal heating wire: nickel chromium alloy resistance wire, or iron chromium aluminum wire material.

d) The electric heat pipe port is sealed with silicone rubber.

For the connection of the heating pipe, the connection mode of the defrosting electric heating pipe indicates that Y is a star-shaped connection, Y must be connected to the middle line, and those that are not indicated are triangular connections. For example, the defrost heater tube of the chiller is generally 220V, and one end of each defrost heater tube is connected to the fire line, and the other end is connected to the neutral line. In addition, the input power marked on the housing of the heating tube is generally the rated power of the heating tube.

The electric defrosting method is simple and easy to operate, but the power of the defrosting heating tube is generally large, and if the quality of the heating tube is not good or it is used for a long time, it is easy to burn out or even cause fire, so the electric defrosting method has serious safety risks and needs to be inspected frequently. The defrost heater tube is generally prone to the following damage:

1. From the appearance, it can be observed that the leading rod is damaged, the metal surface coating is damaged, the insulator is damaged or the seal fails.

2, the physical and chemical properties of the heating tube have changed and can not meet the requirements of use. For example, one of the following circumstances can no longer be used:

① The resistance voltage of the heating tube is lower than the standard value, the leakage current value is greater than 5mA or the insulation resistance value is less than 1MΩ

(2) The shell has flame emission and molten matter, and the surface is seriously corroded or otherwise not allowed to be repaired.

③ The actual power of the heating tube exceeds the rated power by ±10%.

④ The shape of the heating tube has been seriously changed, resulting in the thickness of the insulation layer is obviously uneven, and the insulation performance is significantly reduced by measurement, which does not meet the relevant standards.

Post time: Nov-19-2024