Stainless steel electric heating tube is currently widely used in industrial electric heating, auxiliary heating and thermal insulation electric elements, compared with fuel heating, can effectively reduce environmental pollution. The component structure is made of (domestic and imported) stainless steel as the shell, resistance wire automatically formed by wire winding machine as the heating body, high temperature oxidation powder as the thermal insulation layer, leading rod, insulating sealing materials and accessories by precision machining.

The working principle of the electric tubular heater heating element is that when there is a current in the high temperature resistance wire, the heat generated is transmitted to the surface of the stainless steel tube through the modified oxide powder, and then conducted to the heated part. This structure is not only advanced, high thermal efficiency, fast heating, and uniform heating, the product in the power heating, the tube surface insulation is not charged, safe and reliable use.

Features of stainless steel tubular heating tube:

1, pipe technology: welded pipe, seamless pipe

2, voltage: 12-660V

3, power: according to the heating medium and tube length design;

4, resistance wire: nickel chromium alloy, iron chromium aluminum alloy;

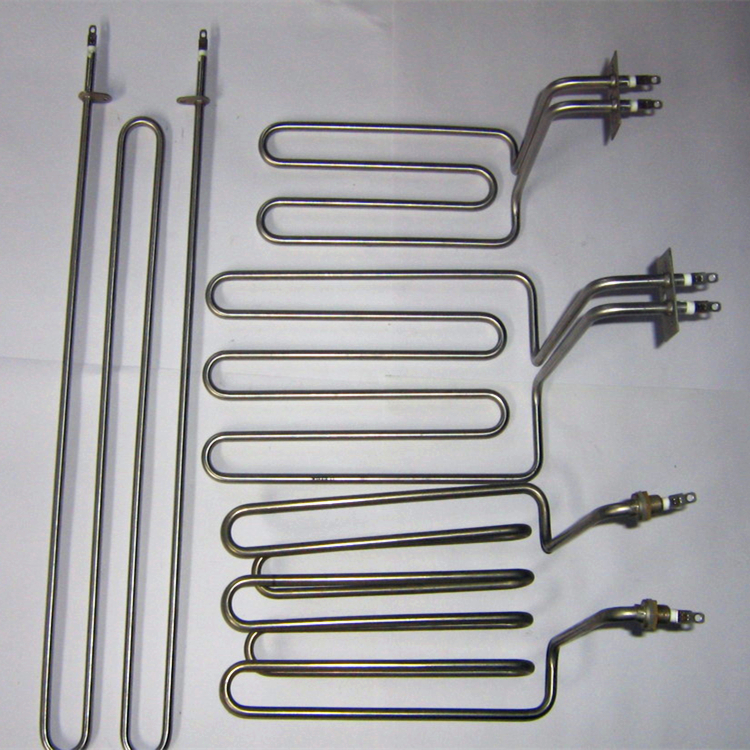

5, shape: straight rod type, U (W) type, fin type, buckle flange type, plane flange type, special shape, etc

6, tube diameter: Φ3mm-30mm, single tube length: 15mm-6000mm, temperature optional range: 0-800℃;

7, pipe material: carbon steel, stainless steel, titanium pipe, imported materials.

The use of stainless steel electric heating tube is very convenient, only need to connect the power to control the opening and closing, so the stainless steel electric heating tube has received wide recognition in the daily heating equipment.

Post time: Dec-15-2023