Defrosting heating elements are a key component of refrigeration systems, especially in freezers and refrigerators. Its main function is to prevent the accumulation of ice and frost in the appliance, ensuring optimal performance and temperature regulation. Let’s take a closer look at how this defrost heater works.

The refrigeration system works by transferring heat from the inside of the unit to the outside environment, thus making the internal temperature lower. However, during normal operation, moisture in the air condenses and freezes on the cooling coils, forming ice. Over time, this ice buildup can reduce the efficiency of refrigerators and freezers, hindering their ability to maintain a constant temperature.

The defrosting tube heater solves this problem by periodically heating the evaporator coils that normally form ice. This controlled heating melts the accumulated ice, allowing it to drain out as water and preventing excessive accumulation.

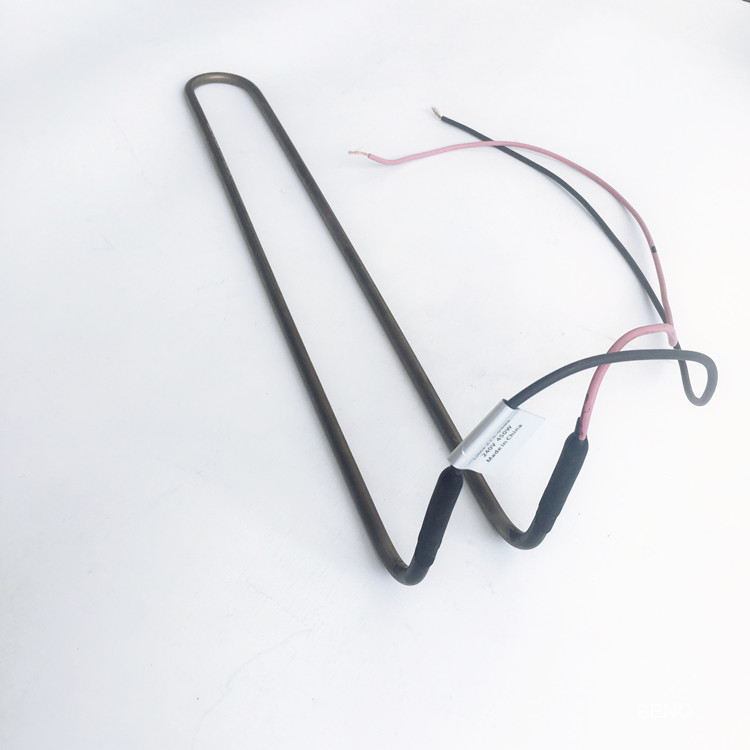

Electric defrosting heating elements are one of the most commonly used types in refrigeration systems. They consist of a resistive wire that heats up when an electric current passes through it. These elements are cleverly placed on the evaporator coil.

Once activated, the current generates heat, heating the coils and melting the ice. Once the defrosting cycle is over, the element stops heating and the refrigerator or freezer returns to regular cooling mode.

Another method used in some industrial refrigeration systems is hot gas defrosting. Instead of using electrical components, the technology uses the refrigerant itself, which is compressed and heated before being guided to the evaporator coil. The hot gas heats up the coil, causing the ice to melt and drain out.

Refrigerators and freezers are equipped with a control system that monitors temperature and ice buildup. When the system detects significant ice accumulation on the evaporator coil, it triggers a defrost cycle.

In the case of an electric defrosting heater, the control system sends a signal to activate the heating element. The element begins to generate heat, raising the temperature of the coil above freezing.

As the coil heats up, the ice above it begins to melt. The water from the melting ice flows into a drainage tray or through a drainage system that is designed to collect and remove water from the unit.

Once the control system determines that enough ice has melted, it deactivates the defrosting element. The system then returns to normal cooling mode and the cooling cycle continues.

Refrigerators and freezers usually undergo regular automatic defrosting cycles, ensuring that ice buildup is kept to a minimum. Some units also offer manual defrosting options, allowing users to start defrosting cycles as needed.

Ensuring that the drainage system remains unimpeded is the key to effective defrosting. Clogged drains can lead to stagnant water and potential leaks. Regular inspection of the defrosting element is essential to verify its function. If this element fails, excessive ice buildup and reduced cooling efficiency may result.

Defrosting elements play a vital role in maintaining the performance of refrigeration systems by preventing ice buildup. Whether through resistance or hot gas methods, these elements ensure that the cooling coils do not have too much ice, allowing the equipment to operate efficiently and maintain an optimal temperature.

Contact: Amiee

Email: info@benoelectric.com

Tel: +86 15268490327

Wechat /whatsApp: +86 15268490327

Skype ID: amiee19940314

Website: www.jingweiheat.com

Post time: Jan-25-2024