There are many things to consider when picking the right flanged immersion heater for your application such as wattage, watts per square inch, sheath material, flange size and much more.

When scale or carbon is found on the surface of the tube body, it should be cleaned and reused in time to avoid heat dissipation and shorten the service life.

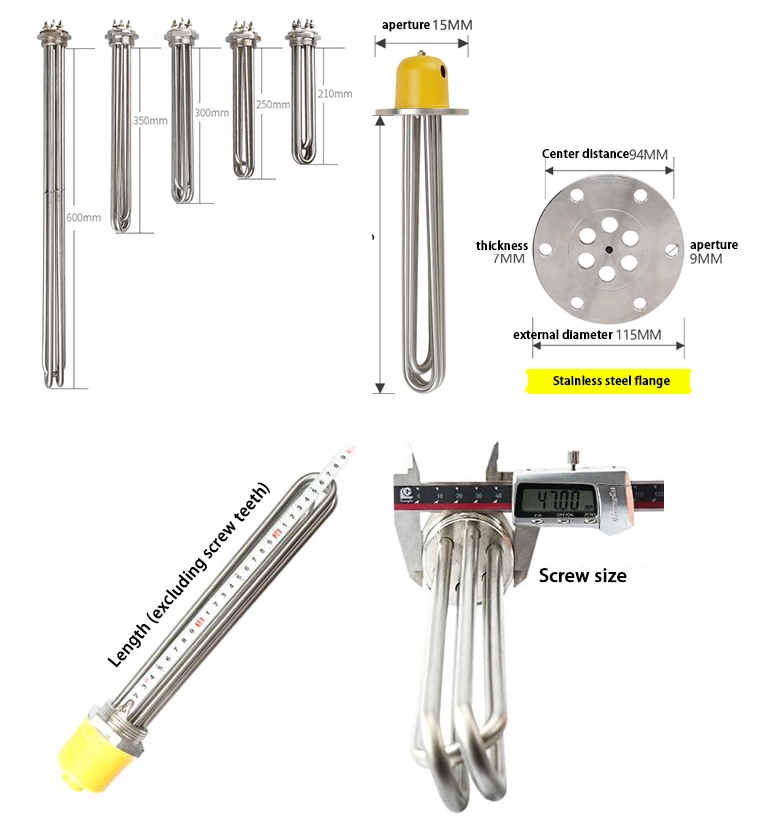

What should be considered when designing the flange immersion heater?

1. Material selection

Common water tank immersion heater element adop stainless steel 304 material, if the scale is more serious ,you can use anti-scale coating flange heater. If you heat some water with weak acids and weak alkalis, you should use stainless steel 316 material, so that the life of the heating element will be effectively guaranteed.

2. Power design

The greater the power per unit length, the shorter life of flange heater of the water tank. If the water quality heated is harder, the power per meter should be smaller, as the scale will cover the heating tube, so that the surface temperature of the heating tube can not be distributed, and finally lead to the increase in the internal temperature of the heating tube, the internal temperature is too high, and the resistance wire will be burned out, and the heating element will expand seriously, and the tube will burst.

3. Installation precautions

Determine whether a cold zone needs to be reserved according to different installation methods. If the flange immersion heater is installed vertically, reserve a cold zone according to the lowest liquid level height of the water tank. This is done to avoid dry burning of the heating area from the water surface. The best installation method is to install the tank heating pipe horizontally below the lowest level of the tank, so that the heating pipe can avoid dry burning.

Post time: Oct-11-2024