The immersion flange heating element is often used in industrial water tanks, thermal oil furnaces, boilers and other liquid equipment, in the use process due to mistakes in the liquid reduction in the case of continued heating, or even empty burning. Such a result will often make the heating pipe burn out, in case of accidents. So what should we know, what should we pay attention to?

The stainless steel heating tube is divided into liquid heating tube and dry heating tube because its own surface load design is not the same. Usually, the surface load of the liquid electric heating tube is much higher than that of the dry heating. Because the liquid electric tube is heated in the liquid, the heat on the surface of the heating tube is easily absorbed by the liquid, so that the surface temperature of the heating tube is not too high, so the surface load design of the liquid heating tube can be higher.

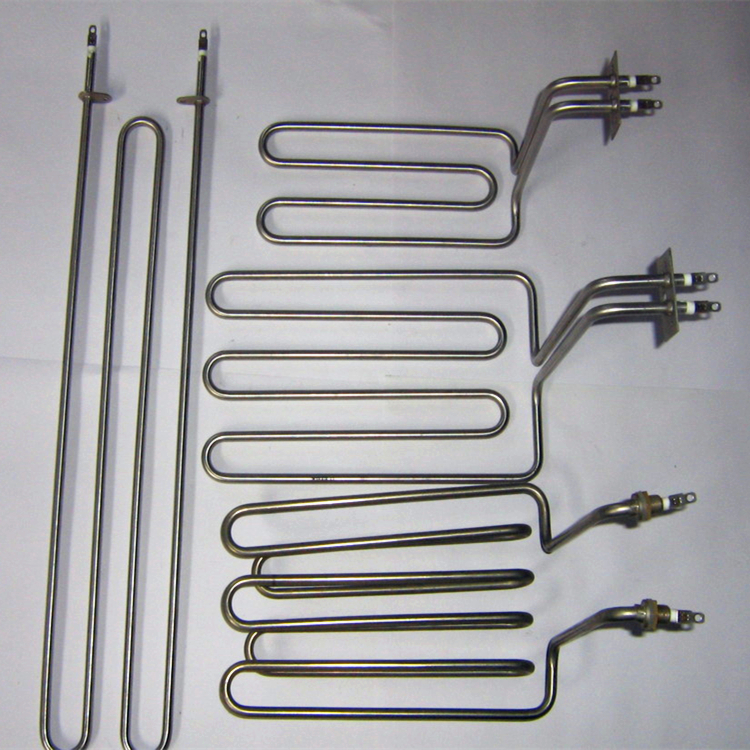

The immersion flange heater tube, because the working environment is in the air, the air itself has a negative effect of hindering heat conduction, so the surface load of the dry heating tube is low. If the liquid electric heating tube appears dry burning phenomenon, the surface temperature of the heating tube cannot be immediately dispersed, and the heating tube will cause the internal temperature to be too high, which will cause the heating tube to burn off, and the tube will explode seriously.

The quality of stainless steel heating pipe has a direct relationship with the manufacturer, and in the choice of products, we must be careful. JINGWEI heater has been engaged in the heating pipe industry for more than ten years. The products are used in many supporting manufacturers and have rich experience. The product quality can be guaranteed.

Post time: Aug-05-2024