Product Paramenters

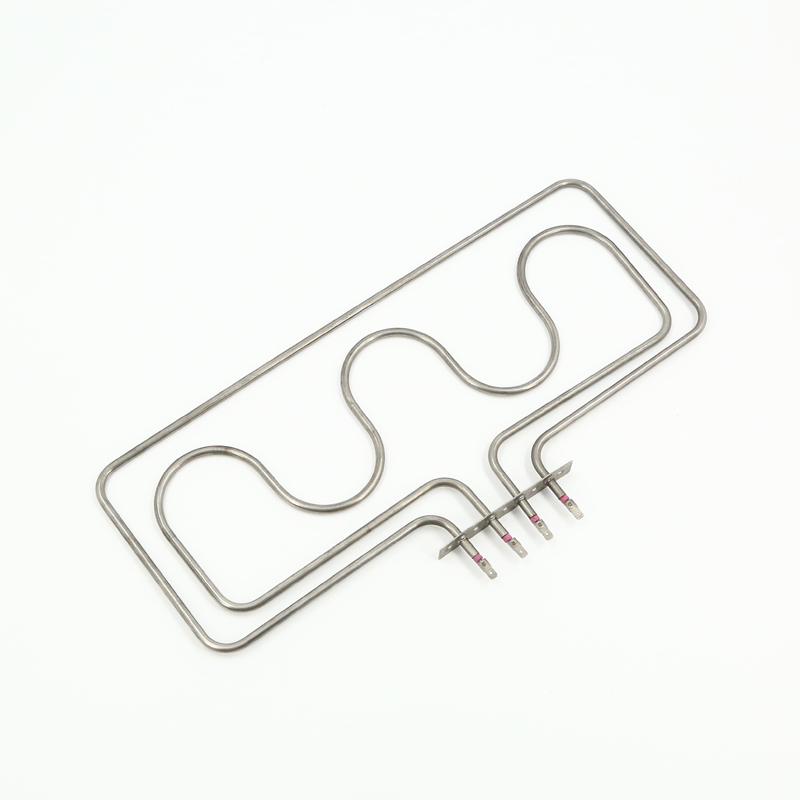

| Porduct Name | Oven Stainless Heating Elements Manufacturers |

| Humidity State Insulation Resistance | ≥200MΩ |

| Material | stainless steel304,or custom. |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

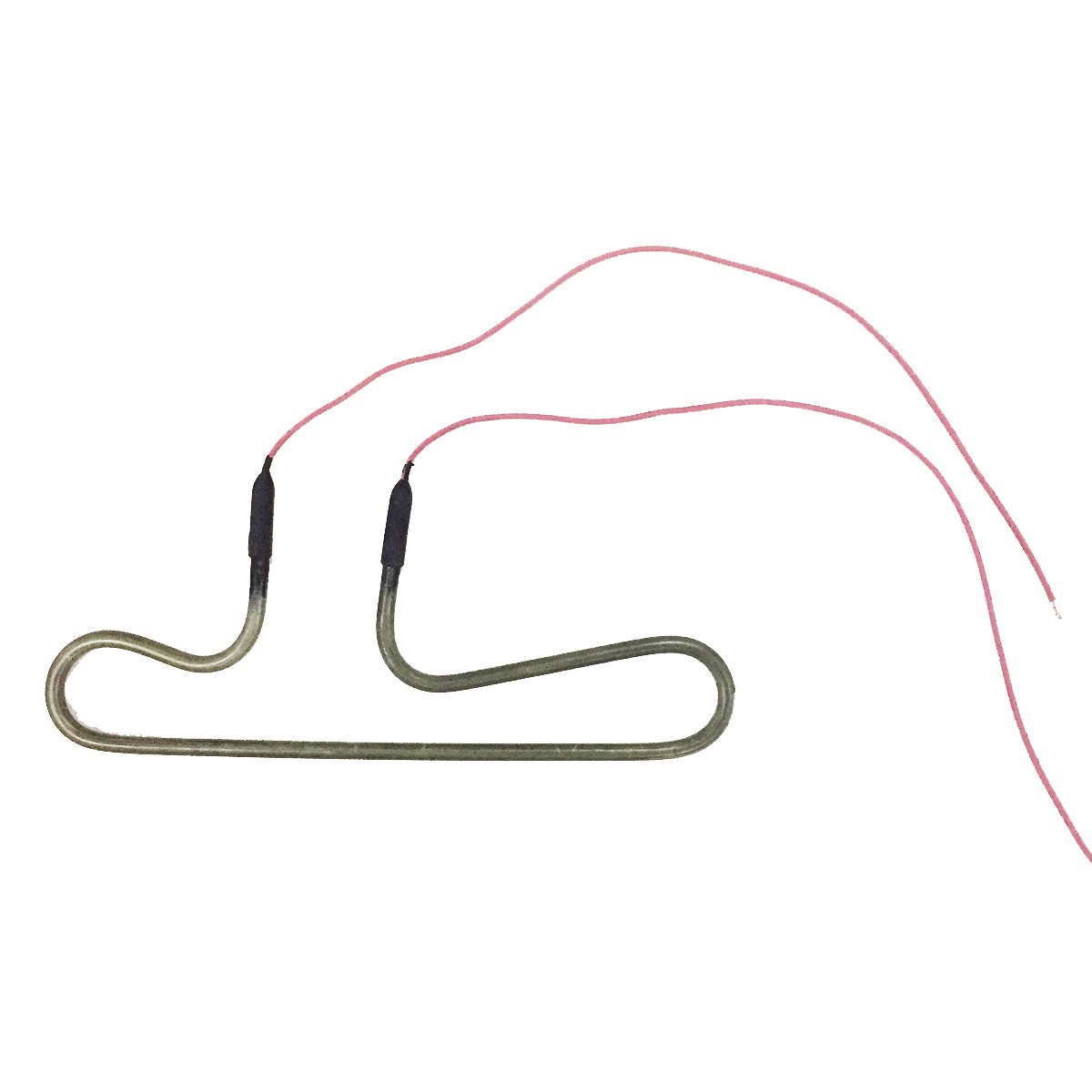

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage | 2,000V/min |

| Insulated resistance in water | 750MOhm |

| Use | Oven Heating Element |

| Tube length | 300-7500mm |

| Shape | customized |

| Approvals | CE/ CQC |

| Terminal type | Customized |

|

The oven heating element is used for the microwave,stove,electric grill.Shape of the oven heater can be customized as client’s drawings or samples.The tube diameter can be choosed 6.5mm,8.0mm or 10.7mm. JINGWEI HEATER is the professional heating tube factory,the voltage and power of oven heating element can be customized as required.And the oven heating element tube can be annealed,the tube color will be dark green after annealing.We have many kinds of the terminal models,if you need add the terminal,you need send us the model number first. |

|

Product Configuration

The oven heating tube is categorized as a dry-burning heating tube.An electric heating tube that is exposed to the air and burns dry is called a dry-burning electric heating tube.The oven heating element consists of a heating wire inside, with modified MgO powder insulating the middle section and providing forced convection heat. We frequently notice that the oven's heater tube is dark green rather than dirty or gray because the exterior surface body of the heater tube is made of dark green stainless steel that has undergone green treatment.

Product Features

1. High-temperature resistance: Tubular Oven Heating Elements can withstand temperatures of up to 1400℃, making them suitable for a wide range of industrial applications.

2. Fast heating: tubular oven heating elements have a high watt density that enables them to heat up quickly, reducing heating time and increasing efficiency.

3. Durability: Tubular Oven Heating Elements are made of high-quality materials that offer exceptional durability and resistance against corrosion and oxidation.

4. Customizable: These oven heating elements can be made to fit specific applications, with options for different sizes, shapes, and wattages available.

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314