Product Configuration

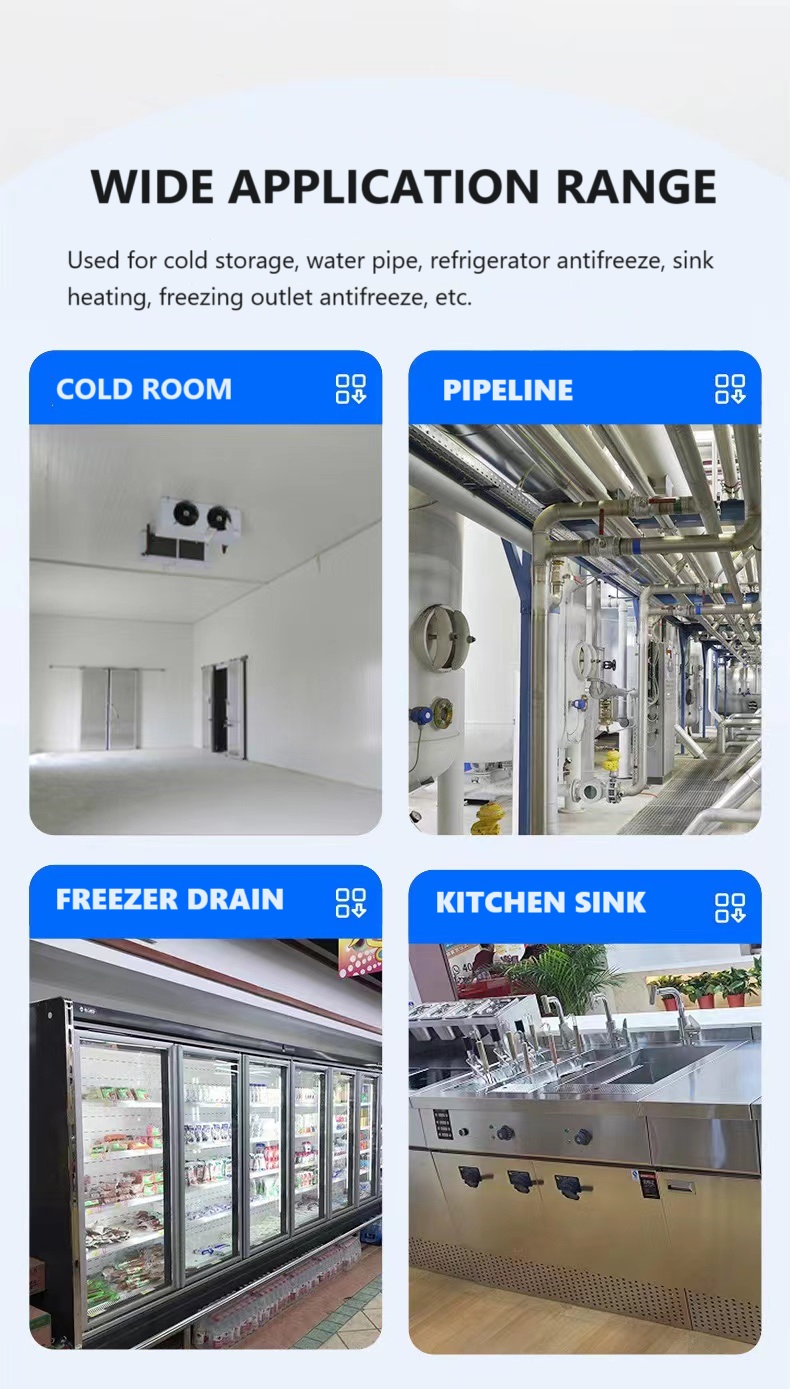

PVC door frame defrost heater is an electric heating element widely used in low-temperature heating scenarios. With its outstanding performance and diverse application scenarios, the defrost heating cable holds an important position in industries, household appliances, and medical equipment fields.

The core components of PVC door frame heating cable include electric heating wires and a PVC insulation layer. The electric heating wires are typically made of materials such as nickel-chromium alloys, which have high resistivity and good oxidation resistance, ensuring stable heating performance over long periods of use. The PVC insulation layer provides excellent protection for the cable, endowing it with flexibility, corrosion resistance, and outstanding insulation properties. These characteristics enable PVC heating wire cables to operate stably in various complex environments.

Common PVC door frame defrost heating wire cables use insulating materials that can withstand temperatures up to 105°C, ensuring the reliability and safety of the cables under high-temperature conditions. Therefore, The PVC defrost wire heater cable is highly suitable for scenarios requiring precise temperature control, such as the compensation heating system in the freezer compartment of a refrigerator. By installing such heating wires in the freezer, frost formation can be effectively prevented, thereby enhancing the refrigeration efficiency and extending the lifespan of the equipment. Additionally, the PVC defrost heating cable is widely used in medical devices, such as blood refrigerators or laboratory temperature-controlled apparatus, to ensure that sensitive items are preserved within an appropriate temperature range.

Product Paramenters

| Porduct Name | PVC Material Defrost Door Frame Heater Wire for Freezer |

| Insulation Material | Silicone rubber |

| Wire diameter | 2.5mm,3.0mm,4.0mm,etc. |

| Heating length | customized |

| Lead wire length | 1000mm,or custom |

| Color | white,grey,red,blue,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | defrost heating wire |

| Certification | CE |

| Package | one heater with one bag |

| Company | Factory/supplier/manufacturer |

|

The PVC door frame defrost wire heater length,voltage and power can be customized as required.The PVC heating cable wire diameter can be choosed 2.5mm,3.0mm,3.5mm,and 4.0mm.The wire surface can be braided firberglass,aluminum or stainless steel. The defrost wire heater heating part with lead wire connector can be seal with rubber head or double-wall shrinkable tube,you can choose according to your own use needs. |

|

To meet the diverse needs of different customers, we offer PVC defrost heating wire products in various specifications. Depending on the actual application, heating wires of different diameters can be selected and paired with single or double layers of 105°C PVC insulation. For higher-demanding application scenarios, a version with a metal braid layer is also available. This design not only enhances the mechanical strength of the cable but also provides grounding protection, further improving the safety and stability of the system.

Product Function

Cold storage door frame heating wire is not long-term energized. The working principle of the defrost wire heater is based on Joule's law, which is that the current converts electrical energy into heat energy. Electric heating means that after the current passes through the conductor, the current will generate a certain amount of heat and be transferred by the conductor. The defrost door heater wire itself is a metal conductor, and it will emit heat after being energized, thereby providing heat to melt the frozen door crack and prevent the door crack from freezing to death. After the electric heating wire is energized for a period of time, it will automatically cut off the power supply. The heating line will hold heat for a period of time, and after the temperature drops, it needs to be re-energized for heating.

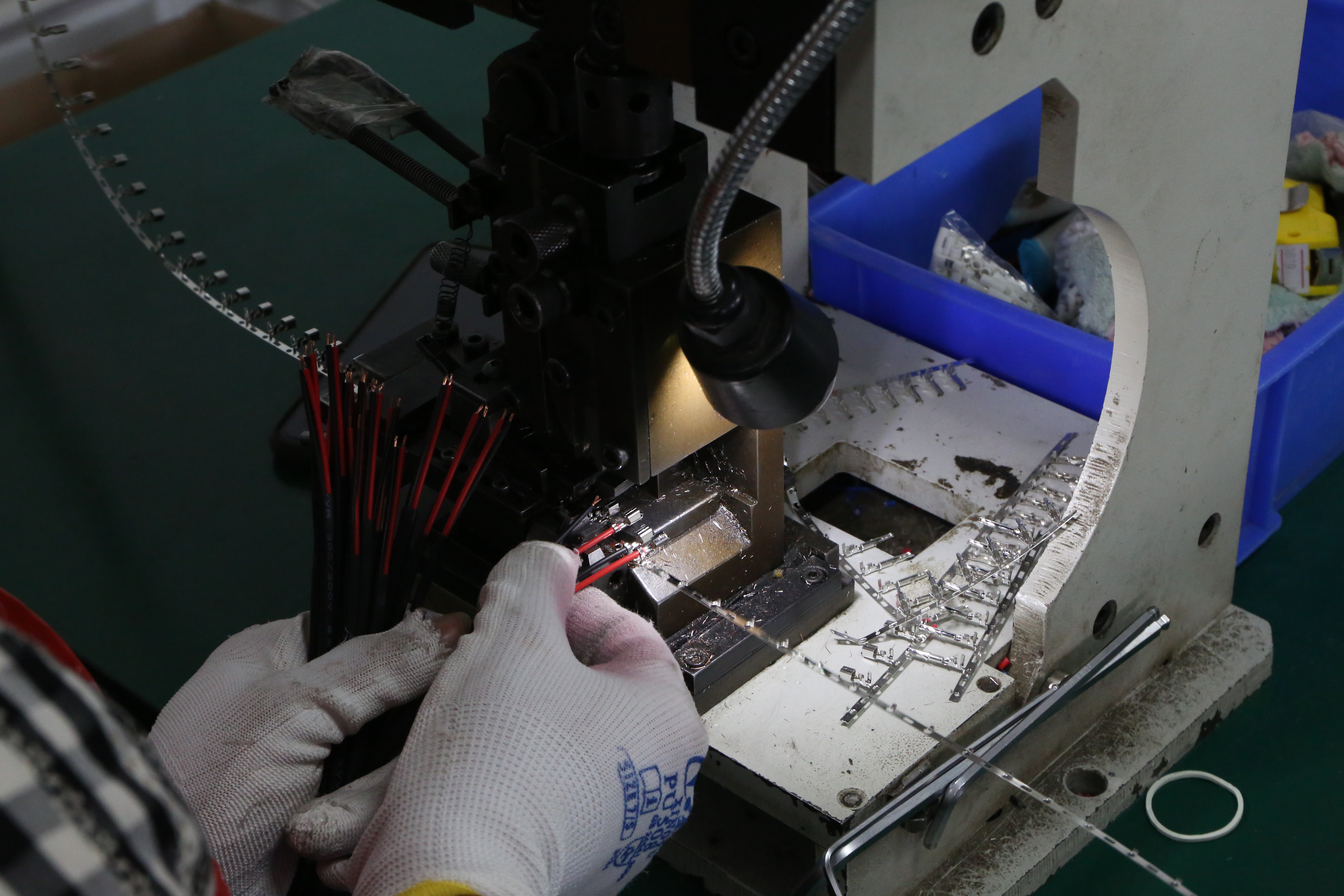

Factory Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314