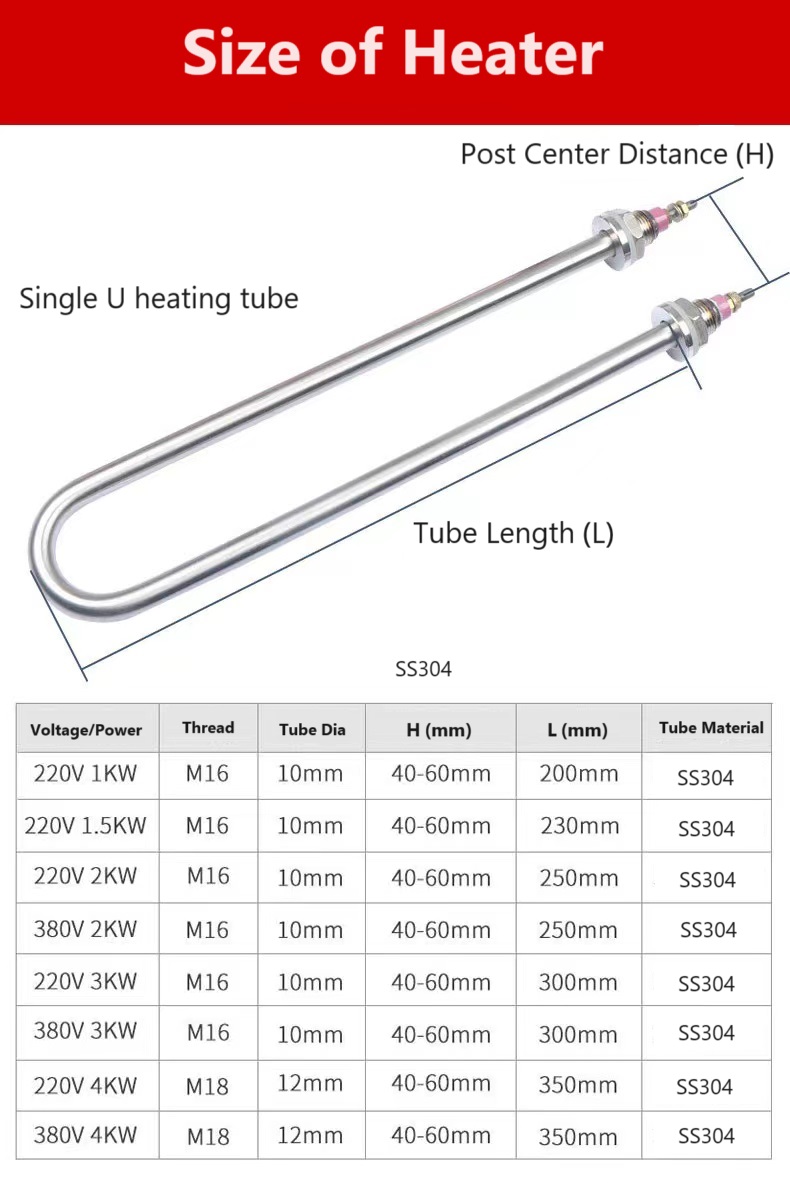

Product Paramenters

| Porduct Name | U Shape Tubular Heating Element for Commercial Food Steamer |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage | 2,000V/min |

| Insulated resistance in water | 750MOhm |

| Use | Immersion Heating Element |

| Tube length | 300-7500mm |

| Shape | customized |

| Approvals | CE/ CQC |

| Terminal type | Customized |

|

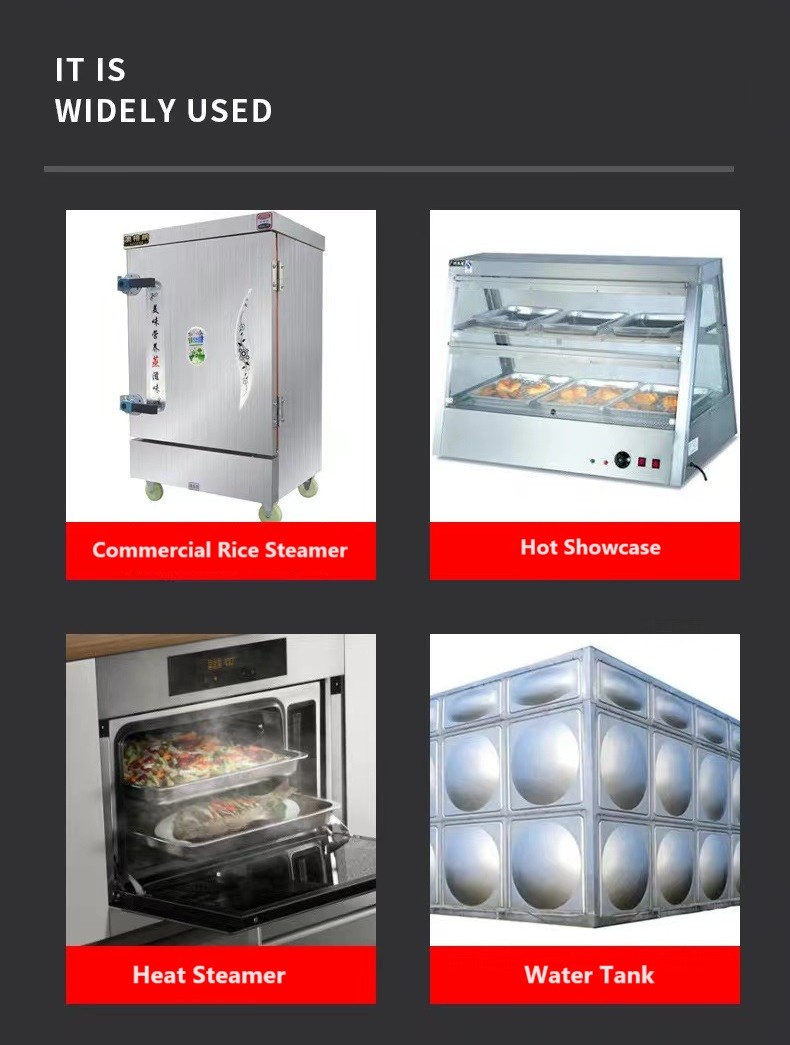

The Tubular Heating Element for Commercial Food Steamermaterial we have stainless steel 201 and stainless steel 304.The Electric Tubular Heater Heating Element is used for the commercial kitchenware,such as rice steamer,heat steamer,hot showcase,etc.The U shape heating tube size can be customized as client’s requirements.Tube diameter can be choosed 6.5mm,8.0mm,10.7mm,etc. |

|

Product Configuration

The structure of the electric U shape heating tube is to put an electric heating wire in a metal tube, and the gap part is tightly filled with crystalline magnesium oxide with good thermal conductivity and insulation. The two ends of the electric heating wire are connected with the power supply through two leading rods. The tubular heating element has the advantages of simple structure, long life, high thermal efficiency, good mechanical strength, and can be bent into various shapes and safe use. High quality materials and strict technology are used to make electric heating tubes with excellent electrical insulation properties and high electrical strength. Stainless stee tubular heater elements are widely used in: water tank, oil tank, boiler, oven, plating tank, load box, high temperature kiln and other industrial equipment and sauna room, electric oven and other civil electrical equipment.

Electric Heating Tube Precautions

1. Components are allowed to work under the following conditions:

(1) The relative humidity of the air is not more than 95%;

(2) The working voltage is not more than 1.1 times the rated value, and the housing should be effectively grounded.

2. when the heating medium is liquid, the effective length of the component (H1 or H2) must be fully immersed in the liquid. The heating part of the component should have a certain distance from the container wall, generally more than 50-60mm.

3. Components that heat liquids shall not be used to heat gases or solids.

4. heating liquid components, such as scale or carbon on the surface of the pipe, should be removed after use, so as not to affect the service life of the components and reduce thermal efficiency.

5. melting light metal or salt, alkali, asphalt, paraffin, etc. for solid heating, should be reduced voltage start, until the solid heating medium all melted to rise to the rated voltage.

6. Safety measures should be considered when heating nitrate to prevent explosion accidents.

7. the component wiring part should be placed in the insulation layer, heating outside, and avoid contact with corrosive and explosive gases. Keep the outlet end dry and clean to avoid flashover or short circuit. Do not exert too much force when wiring.

8. the end of the component may overflow a small amount of paste, this is the sealing material, does not affect the use, after the power off, the overflow can be wiped clean.

9. the components should be stored in the air circulation, relative humidity is not greater than 85%, no corrosive gas room.

10. after the component is used for a period of time and is not used for a long time and is damp, when the cold insulation resistance is less than 1 trillion ohm, the component can be placed in a drying oven at a temperature of about 200 degrees, or reduce the voltage and direct electric heating, remove the moisture, until it returns to normal.

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314