| Porduct Name | Wholesale Diameter 6.5mm Defrost Heater |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm. |

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Defrost Heating Element |

| Tube length | 300-7500mm |

| Lead wire length | 700-1000mm (custom) |

| Approvals | CE/ CQC |

| Terminal type | Customized |

|

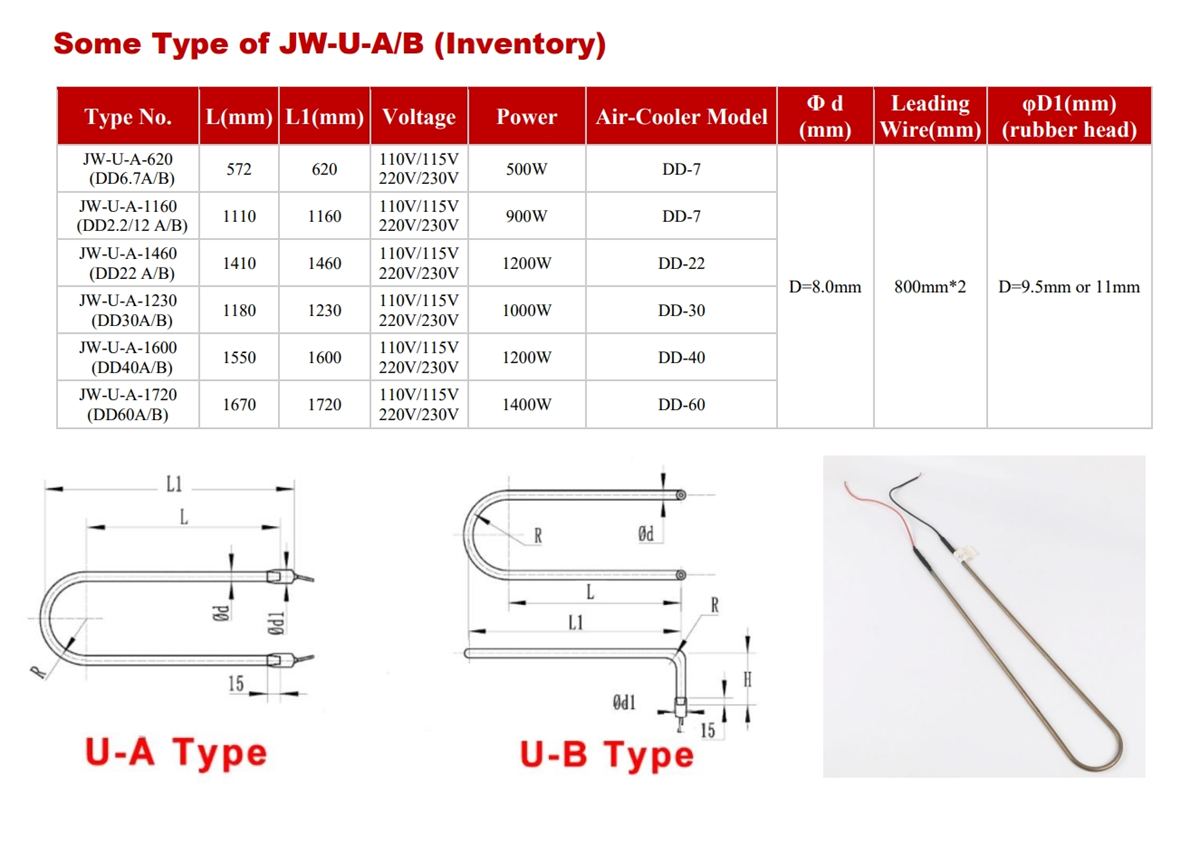

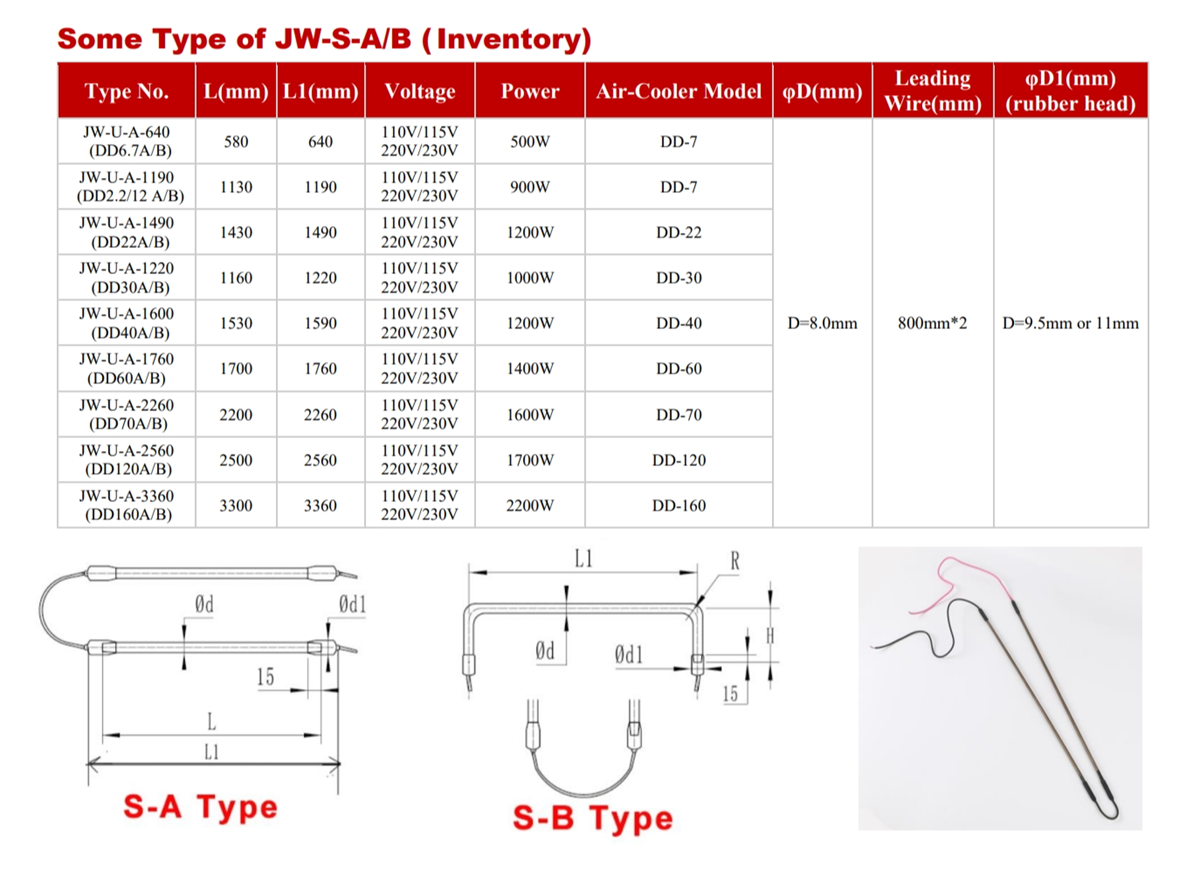

This 6.5mm defrost heater is installed in the refrigerator,freezer and fridge.The tube diameter is 6.5mm and the length of tube can be made from 10inch to 26inch.Terminal can be customized as requirements. INGWEI heater can also be customized defrost heating tube for unit cooler and air condition.The tube diameter can also be choosed 8.0mm and 10.7mm,defrost heater shape can be made straight,double straight tube,U shape ,W shape,or any special custom shape. |

|

The 6.5mm defrost heater works on the basis of a heating principle that involves evenly distributing high temperature resistance wire inside a high temperature resistant stainless steel pipe and then filling the empty space with crystalline MgO powder, which has good insulation and thermal conductivity qualities. In addition to being highly efficient in terms of heat, this construction also provides even heating. In order to accomplish the goal of heating, when a current flows through the high temperature resistance wire, the heat produced is dispersed to the metal tube's surface via the crystalline MgO powder and subsequently transported to the heated area or the surrounding air. Since the defrost heater tube's shell is composed of metal, it can withstand high temperatures, corrosion, and dry burning.

1. To guarantee the equipment operates efficiently and maintain a constant temperature for food storage, install a defrost heater tube on the refrigerator's evaporator coil to melt any accumulated ice and frost.

2. The defrosting heater tube's primary function is to keep the evaporator coil from freezing, allowing for smooth airflow and efficient freezing of the frozen food.

3. Commercial refrigeration systems: To preserve the integrity of perishable goods, big refrigeration units used in supermarkets, restaurants, and other commercial settings require tubular defrosting heaters.

4. Air conditioning system: Defrosting heaters are used to melt ice and increase the cooling effectiveness of air conditioning machines with cooling coils that are prone to frost.

5. Industrial refrigeration fans: To preserve the effectiveness of their refrigeration systems and guarantee product quality, industries that need extensive refrigeration, such food processing and storage facilities, utilize defrost heaters.

6. Cold rooms and walk-in freezers: To keep the evaporator coils from freezing and to maintain a constant temperature for a large number of perishable objects, use defrost heating tubes in cold rooms and walk-in freezers.

7. Refrigerated display cases: To display frozen or refrigerated goods without running the risk of frost hindering view, establishments such as supermarket and convenience stores utilize refrigerated display cases with defrost heater element.

8. Refrigerated trucks and containers: To avoid icing and guarantee that commodities are kept in optimal condition throughout transit, defrost heaters are used to chill transport systems.